Categories

- News From Haomei (311)

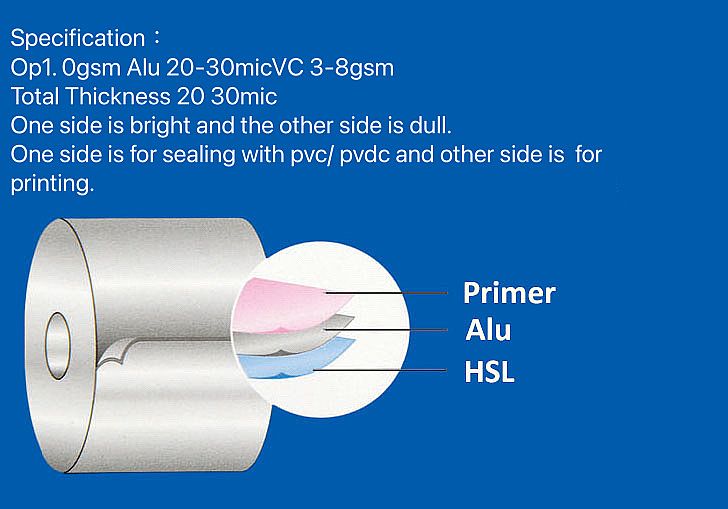

OP/AL/HSL PTP aluminum blister foil is a composite aluminum foil material specifically designed for pharmaceutical blister packaging. Its structure consists of a protective layer (OP), an aluminum foil substrate layer (AL), and a heat-sealing layer (HSL/VC). It features high barrier properties, printability, easy heat sealing, and good mechanical properties, and is widely used in the independent sealing packaging of pharmaceuticals, food, and cosmetics.

Structural composition of OP/AL/HSL PTP aluminum foil:

– Protective layer (OP):

This is the pre-coating layer, usually a transparent or specifically colored film. Its main function is to protect the printed layer on the aluminum foil surface, improve the adhesion of inks to the aluminum foil, and is suitable for various inks such as UV inks, solvent inks, and water-based inks, making the printed pattern clearer and more durable. It also enhances the mechanical strength and weather resistance of the aluminum foil.

– Aluminum foil substrate layer (AL):

This is the aluminum foil layer, usually made of aluminum alloy such as 8011, 8021. It has excellent barrier properties, effectively blocking oxygen, water vapor, and light, protecting the contents from external environmental influences, and extending the product’s shelf life. The aluminum foil layer is the core component of blister packaging, effectively isolating light, oxygen, and water vapor to protect the quality and stability of the packaged medicine.

– Heat-sealing layer (HSL/VC):

This layer is coated on the other side of the aluminum foil and used to heat-seal the package with the rigid plastic sheet (such as PVC, PVDC, PP, PS, etc.) to form a sealed blister package. The heat-sealing layer has good adhesion and heat-sealing strength, ensuring a strong seal between the aluminum foil and the rigid plastic sheet, preventing the medicine from getting damp, oxidized, or contaminated. Different regions have different standards for the amount of heat-sealing varnish used; the Asian standard is generally 3-5g, and the European standard is 6-8g.

Specifications of OP/AL/HSL aluminum blister foil:

Width is generally ≤600mm;

Common thicknesses are 20μm, 25μm, and 30μm;

Inner diameter is 76mm;

Outer diameter is 240mm;

Length is approximately 1000m;

Weight is 60g/㎡ (20μm thickness).

Features of OP/AL/HSL PTP aluminum foil:

– High barrier properties:

The aluminum foil layer effectively isolates the medicine from external environmental influences, extending its shelf life.

– Printability:

The aluminum foil surface can be printed with medicine information, brand logos, and customized designs. The printing is clear, aesthetically pleasing, and glossy, allowing for 1-3 color double-sided printing or full-body single-color printing, meeting the needs of medicine traceability and anti-counterfeiting.

– Easy heat sealing:

The heat-sealing layer has good compatibility with various plastic substrates, supporting stamping and high-speed automated packaging equipment.

– Mechanical properties:

Utilizing 8011 aluminum alloy substrate, ensuring the material is not easily deformed or damaged during processing and use.

Application areas of OP/AL/HSL aluminum foil:

– Pharmaceutical packaging:

Primarily used for independent sealed packaging of solid dosage forms such as tablets, capsules, suppositories, and pills. Also suitable for blister packaging of food products such as candy, chocolate, and chewing gum.

– Food packaging:

Due to its excellent barrier properties, it is also suitable for food packaging with high requirements for moisture and oxygen barrier properties.

– Cosmetic packaging:

Some cosmetics also use blister packaging to protect the product from external environmental influences.