Product Categories

- Dairy & yogurt pack (8)

- Pharmaceutical Pack (13)

- Food & beverage pack (9)

- Pure aluminum foil (7)

- Industrial Aluminum Foil (5)

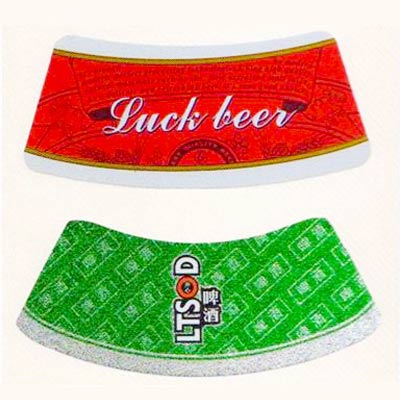

Neck label, front label and back label, for the bottles of beer and wine;Aluminum foil, metalized paper, coated paper, with printing & embossing & die-cutting etc.

Aluminium foil bottle neck labels add visual prestige to any type of bottle. They are a valuable part of the product’s personality and a guarantee of authenticity. Champagne and traditional bottled beers use them as a hallmark of product quality.

But the Aluminium foil is not just there for decoration. It ensures security, providing tamper evidence in the case of ‘over the crown’ Aluminium foil. Aluminium foil’s physical properties of ‘deadfold’ and malleability enable it to mould with the contours of bottles and closures in an easy-to-apply and brand building way. Opening a twist-off cap or crown closure is easily done without disturbing the appearance of the neck foil thanks to tear off perforation. The art and technology of bottle neck foils is moving ahead continually, resulting in material savings whilst retaining elegant appearance and high product security. Champagne capsules are generally made from thicker gauge aluminium foil which is sometimes coated or laminated with a plastic layer. Aluminium foil has been adopted as the natural successor to lead as the material for spin-on capsules for wine bottles. Neck foils are frequently embossed which, apart from giving a distinctive appearance, also makes the labels easy to handle. Other developments have also enabled smooth labels to be used. Labels with partial embossing adding an element of design appeal and individuality are a further option.

1.Material: pure aluminium foil/aluminum foil

2.Thickness: 0.0105mm

3:Temper: O(soft)

4.Embossing: Yes.

5.MOQ:2 Tons

6.food-grade material, without odor, fading

7.color, design, size can be customized.

8.Packaging: Wood box

Usage: For wine bottle,beer bottle’s neck and body labels.

| Designation | Beer Neck Label Foil |

| Application | Beer Neck Wrapping Label |

| Alloy & Temper | 8011–O, 1235-O |

| Thickness | 0.01 mm–0.012 mm |

| Width | 360 mm–1600 mm |

| Finishing | Single-Sided |

| Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

| Each | Total | |||||||||||

| 8011 | 0.6~1.0 | 0.50~0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | – | 0.08 | 0.05 | 0.15 | Remains |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | — | 0.1 | – | 0.06 | 0.05 | 0.05 | Remains | |

| Alloy | Temper | Thickness (mm) | Test under room temperature | ||

| Tensile Strength Rm/(N/mm2) | Elongation %(>=) | ||||

| A50mm | A100mm | ||||

| 8011/1235 | O | 0.0060~0.0090 | 45~100 | 0.5 | |

| >0.0090~0.0120 | 60~100 | – | 1.5 | ||