Product Categories

- Dairy & yogurt pack (8)

- Pharmaceutical Pack (13)

- Food & beverage pack (9)

- Pure aluminum foil (7)

- Industrial Aluminum Foil (5)

1000 series: 1235、1060、1050、1100

3000 series: 3003、3004

8000 series: 8011、8021、8079

Material temper: O、H14、H16、H18、H19、H24 etc.

Thickness(mm): 0.014-0.2

Width(mm): 20-1600

The food grade aluminium foil produced by Haomei Aluminum has the characteristics of non-toxic, light-shielding, good air tightness, excellent ductility and high recovery rate. In addition, through different processing techniques, the manufactured food grade aluminium foil can fully meet the requirements of various food packaging. For example, the popular disposable lunch boxes, favorite BBQ household foils, tart cups, yogurt lids, and other delicious packaging are all made of food grade aluminium foil!

Aluminium foil is a superior household material for food packaging which can resist water and oil. It can be reused and can isolate light and conduct heat. Because of these features, it is widely used in the food packaging industry. Here, the most noteworthy is that Haomei food grade aluminum foil has obtained the FDA and SGS certification! And we can rest assured to purchase and use!

Specification of food grade aluminium foil

| 1000 series | 1235、1060、1050、1100 aluminum foil |

| 3000 series | 3003、3004 |

| 8000 series | 8011、8021、8079 aluminum foil |

| Material temper | O、H14、H16、H18、H19、H24 etc. |

| Thickness(mm) | 0.014-0.2 |

| Width(mm) | 20-1600 |

Advantages of Food Grade Aluminum Foil

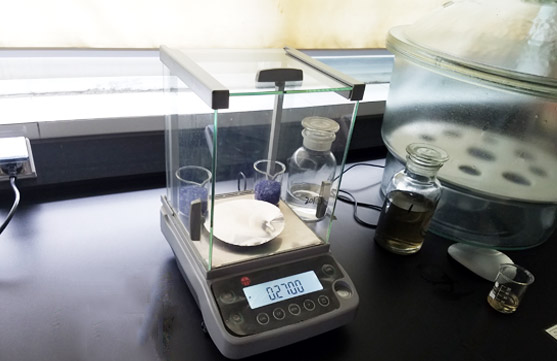

1, Haomei uses Honeywell thickness gauge to accurately control the thickness of aluminum foil produced. And with first-class equipment and top-level instruments, it guarantees the printing effect and mechanical properties of food packaging foil, and improves the product’s air separation performance and temperature resistance.

2, As one of the aluminium foil manufacturers, food grade aluminum foil produced by Haomei, the version is flat, reaching the brush A grade, no black oil spots, bright lines, small black silk, etc., no mosquitoes to join, safe and sanitary.

3, Using natural gas annealing, the temperature rises quickly, the annealing effect is good, and the processed food grade aluminum foil has good performance and high quality.

Application of food grade foil

1, For Disposable food Containers

Common grade alloys are 1100/3003/3004/5052/8011/8006/8079 food grade aluminium foil. Among them, 3003 aluminium foil has higher tensile strength and elongation than 1100 and 8011 alloy foil, which can better meet the production needs of lunch boxes and containers with three cavities, multiple cavities or complex shapes. The yield rate is over 95%! In addition, 8079/8006 aluminum foil is a special raw material for aerospace non-wrinkle lunch box containers. It has a higher cup convexity, and the edges of the stamped disposable lunch boxes have no wrinkles, the appearance is high-grade and beautiful.

2, Household Foil

Common grade alloys are 1235/1100/1070/1060 food grade aluminium foil, which has great demand, and is widely used in BBQ, egg tarts, bread and other disposable food packages. Due to the low production cost of these food packaging aluminium foils, it is very suitable for mass production of disposable food packages.

3, Food Grade Aluminium Foil for Yogurt Lid

Food grade aluminium foil is used as the material of the middle layer of the yogurt lid. The commonly used alloy is 8011 aluminum foil with a thickness of 0.038-0.048mm, and O temper. Because 8011 aluminum foil for yogurt lid contains Mn and Mg elements, it has strong acid resistance, which effectively guarantees the perfect taste of yogurt, jelly, milk tea and other fruit acids! Besides, for the yogurt lid foil with higher elongation requirements, 8021 and 8079 aluminum foil can be used.

4, Food Aluminum Foil Bag

Beef, cooked meat, sausage, nuts, chocolate beans and other delicious food aluminum foil bags, mainly using 1060, 1100, 3003, 8011, 8021 food grade aluminium foil, commonly used temper status includes h14, h16 and h18.

Q: Are you a manufacturer?

A: We are a large factory located in Henan, China, specialized in producing marine grade aluminum sheets, aluminium sheet/coil/foil, color coated aluminium, embossed aluminium, mirror polished aluminium, etc for many years.

Q: What's your complete production procedure?

A: Primary Smelting - Refining - Ingotting - hot rolling tandem casting - rolling - cleaning - leveling - Rolling - Annealing - Rolling to finished products - Packing - Delivering;

Q: What's our advantages as a supplier?

A: 1) purchasing high quality aluminium ingot,

2) advanced equipment

3) complete production processes

4) strict and professional quality inspectors

5) good quality, short delivery time, good packing, good service;

Q: Do you provide samples?

A: Yes, we can provide samples as the customers' request;

Q: Can I visit your company?

A: Of course, welcome to visit our company any time!