Product Categories

- Dairy & yogurt pack (8)

- Pharmaceutical Pack (13)

- Food & beverage pack (9)

- Pure aluminum foil (7)

- Industrial Aluminum Foil (5)

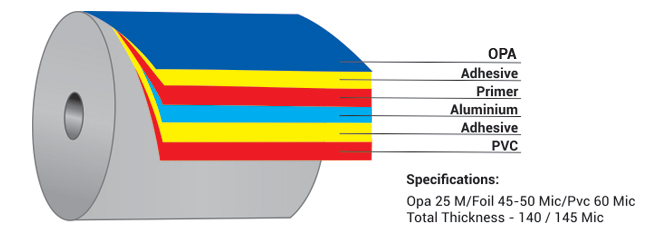

Alu Alu Foil is an excellent multilayered structure Designed for high sensitive range of Pharmaceutical and generic medicines which are highly hygroscopic or light sensitive and cannot be suitably packed with barrier plastic films. The structure is an optimized combination of aluminium foil and polymeric films with the alumina layer sandwiched between an inner heat seal-able polymeric film and outer supportive malleable film.

Widely used in the blister packaging of pharmaceutical & food industries, seal to aluminum blister foil, 600 times the barrier performance than PVC, 100 times the barrier than PVC/PVDC.

Cold formed aluminum foil is at the heart of alu alu OPA/Al/PVC sandwich foils used for pharmaceutical blister pack applications because of their inherently superior advantages. Aluminum, even in micron thickness, is the best vapor and light barrier besides providing aesthetic shine for pharmaceutical blister packs.

Specification:

Thickness: 140 microns – 160 microns

Width: Less than 700 mm

Winding diameter: 240 mm – 280 mm

PVC side sealed with aluminum foil

Hamei alu alu foils possess distinctive features that put them in a class apart:

1.Packaging for small dense blisters

2.Packaging for large capsules

3.Anti-counterfeiting printing and packaging

4.High-speed machine packaging

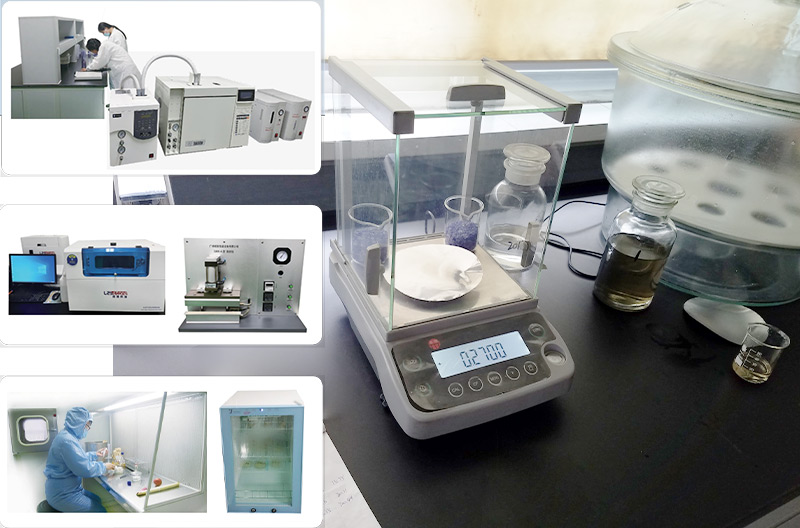

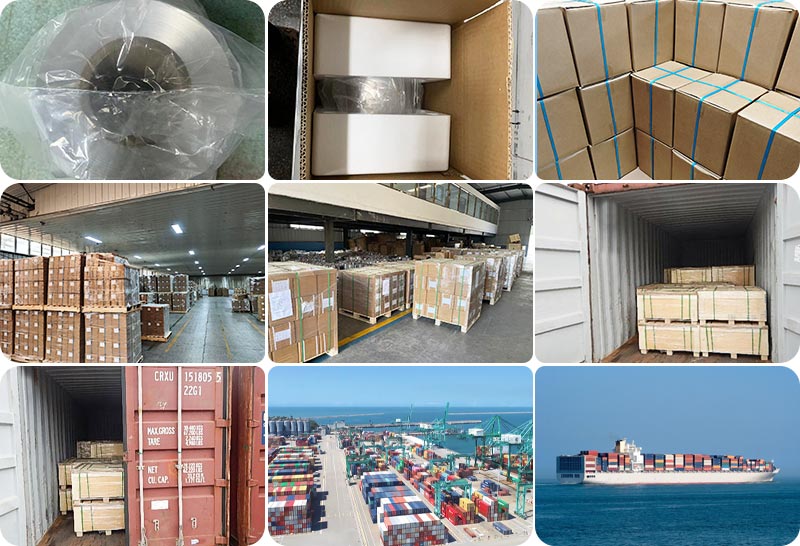

HaoMei Aluminum packaging has domestic technology leading six-roll calendering production line, “class D” purification production workshop; Annual output of 25,000 tons;

Select high quality imported raw materials, pay attention to every detail of production, to provide the most cost-effective packaging materials for pharmaceutical companies.

The laboratory is equipped with good performance of electronic analysis balance, high pressure steam sterilization pot, heat sealing instrument, oxygen penetration tester, meteorological chromatograph, electronic tensile testing machine and other testing equipment.

HaoMei packaging is in strict accordance with the primary pharmaceutical packaging material standard YBB00212005- 2015, ISO9001 quality recognition system, taking into account the requirements of GMP management department of drug manufacturing enterprises and establish a relatively perfect quality management and testing system, with a number of high-quality professional and technical personnel and advanced testing equipment, to provide a strong guarantee for the quality of products.