Categories

- News From Haomei (325)

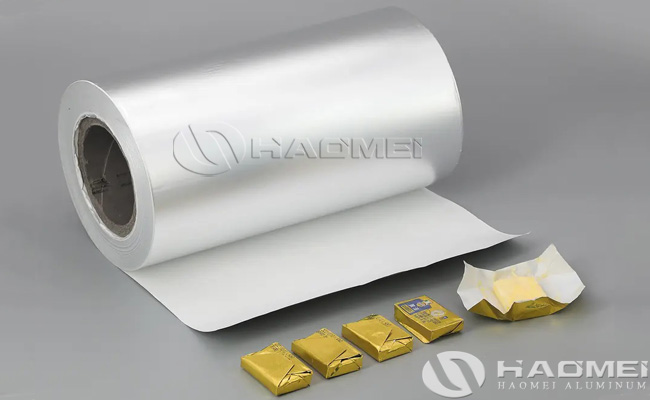

Butter packaging foil paper has outstanding resistance to grease, stable physical properties, non-toxic and tasteless, which can reduce the penetration of grease, but also does not affect the flavor and safety of food. The aluminum foil paper are commonly used in packaging rich in grease food, such as butter, pastry, etc..

The requirements for butter packaging is mainly to protect its aroma beads, tissue, appearance, moisture and color. Airtight packaging is very important, not only to protect its flavor from dissipation, but also to resist the pollution of external odors, because butter can easily absorb foreign odors. Due to the emulsion characteristics of butter, the fat in it is particularly susceptible to oxidation and rancidity.

Butter is usually packaged in parchment, aluminum/sulfuric acid paper or a composite of butter aluminum foil and greaseproof paper. Parchment is brittle and should contain at least 9% moisture and be stored in a clean place free of dust and 50% to 80% humidity. If it is too dry, the parchment will be brittle and break easily when wrapping. Conversely, if it is too humid, mold will easily grow and contaminate the butter. Although parchment is oil resistant, it can still transmit oxygen, and its translucency can transmit light, which can easily promote the oxidation of butter.

For long-term preservation of animal fat protection packaging is still the safest use of aluminum foil composite materials. However, aluminum foil and plastic film composite material is not ideal, because most plastic films are breathable, leading to the loss of butter flavor, and oil resistance is not good. It is better to use aluminum butter packaging foil paper composite material, the paper not only plays a strengthening role, can reduce the thickness of aluminum foil, at the same time, the paper can improve the process operation performance of packaging machine machinery. European countries generally use aluminum foil / parchment composite packaging butter.