категории

- Новости От Haomei (323)

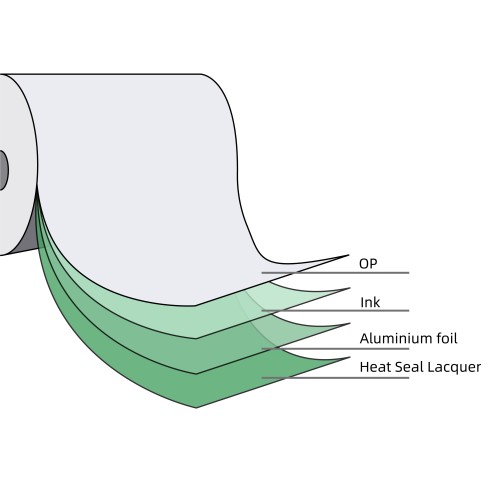

Алюминиевая фольга PTP является основным материалом для фармацевтической блистерной упаковки., отдается предпочтение за свои высокие барьерные свойства, простота обработки и безопасность, что делает его предпочтительным решением для индивидуально запечатанной упаковки таблеток.. Алюминиевая фольга PTP для упаковки таблеток в качестве основного материала используется простая алюминиевая фольга, обработанная посредством печатной графики, покрытие защитным слоем ОП, и нанесение клея VC. Его типичная структура: OP/AL/VC., а именно защитный слой/алюминиевая фольга/термосвариваемый слой, с толщиной обычно около 0,024 мм.

Упаковка таблеток Алюминиевая фольга PTP имеет пятислойную композитную структуру., каждый слой имеет четкую функцию:

– Защитный слой (ОП):

Расположен на самом внешнем слое, повышает устойчивость алюминиевой фольги к истиранию и устойчивость к пятнам, обеспечение четких и долговечных печатных рисунков.

– Внешний печатный слой:

Этот слой печатает информацию о лекарствах. (например, имя, дозировка, и дата производства) с помощью пластины с электрогравировкой или лазерной печатью. В некоторых продуктах используется невидимая флуоресцентная технология защиты от подделок., отображение знаков защиты от подделки в ультрафиолетовом свете для предотвращения подделки.

– Основной материал алюминиевой фольги (Алабама):

В основном изготовлен из алюминиевого сплава 8011-H18., толщиной 0,016-0,04мм, сочетание механической прочности и гибкости. Его плотная металлическая кристаллическая структура эффективно блокирует кислород., водяной пар, и свет. Скорость передачи кислорода составляет ≤0,1 см³/(м² · 24h · 0,1 МПа), и скорость передачи водяного пара составляет ≤0,5 г/(м² · 24 часа), обеспечение стабильности препарата.

– Внутренний печатный слой:

При прямом контакте с препаратом, он должен соответствовать стандартам безопасности пищевых продуктов, чтобы предотвратить загрязнение..

– Термосвариваемый слой (VC):

Использует модифицированное полиэтиленовое покрытие с температурой термосваривания 100-120 ℃.. После склеивания с ПВХ, ПВДХ, и другие жесткие пластиковые листы, сила отрыва остается стабильной на уровне 6-10 Н/15 мм., достижение прочного уплотнения и легкого удаления.

Основные преимущества производительности Алюминиевая фольга ПТП для упаковки таблеток:

– Высокие барьерные свойства:

Слой алюминиевой фольги полностью изолирует свет., кислород, и водяной пар, предотвращение окисления лекарств, поглощение влаги, или фотодеградация, продление срока годности более чем 3 лет.

– Механическая стабильность:

А 8011 Подложка из алюминиевого сплава термостойкая, устойчивый к низким температурам, и устойчивый к коррозии, подходит для высокоскоростных автоматизированных упаковочных линий (скорость до сотен блистерных упаковок в минуту), и не легко повредить во время транспортировки.

– технологичность:

Поддерживает прецизионную резку (ширина ±0,2 мм, длина ±0,3 мм), а специально разработанные канавки можно использовать для фиксации микротаблеток или гранул., предотвращение поломок от ударов.

– Отличные возможности печати:

При необходимости возможна печать на одной или обеих сторонах., с насыщенными цветами и четкими узорами. Возможность печати 1-12 цвета, содействие отображению информации о лекарствах и корпоративному продвижению.

– Безопасность:

Производство должно быть завершено в 100,000-300,000 чистое помещение класса GMP, соответствие национальным стандартам YBB и сертификатам FDA и CFDA.. Нетоксичный и без запаха, обеспечение отсутствия загрязнения лекарственных средств.

Алюминиевая фольга ПТП в основном используется для блистерной упаковки таблеток., капсулы, суппозитории, таблетки, и т.п., а также для блистерной упаковки мелких гранулированных продуктов, таких как шоколадные зерна и конфеты.. более того, его применение в продуктах для здоровья, косметика, и одноразовые медицинские изделия постепенно расширяются.

Алюминиевая фольга ПТП, благодаря своим высоким барьерным свойствам, механическая стабильность, технологичность, и безопасность, стал основным выбором для упаковки таблеток. В фармацевтической промышленности, Алюминиевая фольга ПТП широко используется при упаковке различных таблеток., капсулы, и другие твердые наркотики, и является одним из ключевых материалов для обеспечения безопасности и эффективности лекарственных средств..