categorías

- Noticias de Haomei (323)

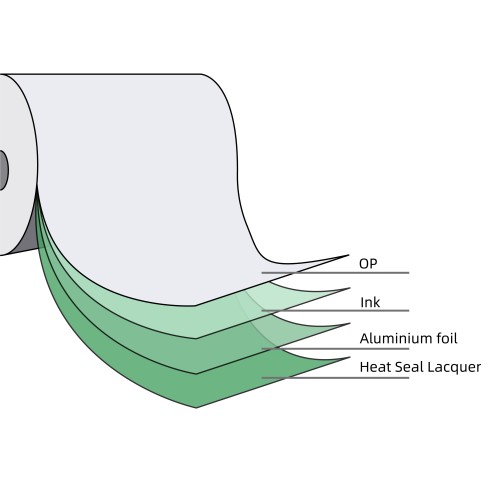

El papel de aluminio PTP es un material central para los envases tipo blíster farmacéuticos., favorecido por sus altas propiedades de barrera, facilidad de procesamiento y seguridad, lo que la convierte en la solución preferida para envases de tabletas sellados individualmente. Papel de aluminio PTP para embalaje de tabletas. utiliza papel de aluminio simple como material base, procesado a través de la impresión de gráficos, revestimiento con una capa protectora OP, y aplicando adhesivo VC. Su estructura típica es OP/AL/VC., a saber, capa protectora/papel de aluminio/capa de sellado térmico, con un espesor generalmente alrededor de 0,024 mm.

El papel de aluminio PTP para embalaje de tabletas emplea una estructura compuesta de cinco capas, con cada capa teniendo una función clara:

– Capa protectora (OP):

Ubicado en la capa más externa., Mejora la resistencia a la abrasión y a las manchas del papel de aluminio., asegurando patrones impresos claros y duraderos.

– Capa exterior impresa.:

Esta capa imprime información sobre medicamentos. (como el nombre, dosificación, y fecha de producción) utilizando una placa electrograbada o impresa con láser. Algunos productos utilizan tecnología antifalsificación fluorescente invisible., Mostrar marcas antifalsificación bajo luz ultravioleta para evitar la falsificación..

– Material base de papel de aluminio (Alabama):

Hecho principalmente de aleación de aluminio 8011-H18, con un espesor de 0,016-0,04 mm, combinando resistencia mecánica y flexibilidad. Su densa estructura cristalina metálica bloquea eficazmente el oxígeno., vapor de agua, y ligero. La tasa de transmisión de oxígeno es ≤0,1 cm³/(m² · 24H · 0.1MPA), y la tasa de transmisión de vapor de agua es ≤0,5 g/(m² · 24h), asegurar la estabilidad del fármaco.

– Capa interior impresa.:

En contacto directo con la droga., debe cumplir con los estándares de seguridad de calidad alimentaria para evitar la contaminación..

– Capa de termosellado (VC):

Utiliza un revestimiento de polietileno modificado con una temperatura de termosellado de 100-120 ℃. Después del pegado con PVC, PVDC, y otras láminas rígidas de plástico, la fuerza de pelado permanece estable en 6-10N/15 mm, logrando un sellado fuerte y fácil extracción.

Principales ventajas de rendimiento de Papel de aluminio PTP para embalaje de tabletas:

– Propiedades de alta barrera:

La capa de papel de aluminio aísla completamente la luz., oxígeno, y vapor de agua, prevenir la oxidación de medicamentos, absorción de humedad, o fotodegradación, extender la vida útil de la plataforma 3 años.

– Estabilidad mecánica:

los 8011 El sustrato de aleación de aluminio es resistente al calor., resistente a bajas temperaturas, y resistente a la corrosión, adecuado para líneas de envasado automatizadas de alta velocidad (acelera hasta cientos de blisters por minuto), y no se daña fácilmente durante el transporte.

– Procesabilidad:

Soporta corte de precisión (ancho ±0,2 mm, longitud ±0,3 mm), y se pueden usar ranuras diseñadas a medida para asegurar microtabletas o gránulos, evitando roturas por impactos.

– Excelente imprimibilidad:

Se puede imprimir en una o ambas caras según sea necesario, con colores ricos y patrones claros. Capaz de imprimir 1-12 colores, Facilitar la exhibición de información sobre medicamentos y promoción corporativa..

– Seguridad:

La producción debe completarse en un 100,000-300,000 sala limpia clase GMP, Cumpliendo con los estándares nacionales YBB y las certificaciones FDA y CFDA.. No tóxico e inodoro, Garantizar que no haya contaminación de los medicamentos..

El papel de aluminio PTP se utiliza principalmente para el envasado en blíster de tabletas., cápsulas, supositorios, píldoras, etcétera, y también para envases tipo blíster de alimentos granulados pequeños, como chocolate en grano y caramelos.. además, su aplicación en productos sanitarios, productos cosméticos, y los dispositivos médicos desechables se están expandiendo gradualmente.

Papel de aluminio PTP, con sus altas propiedades de barrera, estabilidad mecanica, procesabilidad, y seguridad, se ha convertido en la opción principal para el envasado de tabletas. En la industria farmacéutica, El papel de aluminio PTP se utiliza ampliamente en el envasado de varias tabletas., cápsulas, y otras drogas sólidas, y es uno de los materiales clave para garantizar la seguridad y eficacia de los medicamentos..