Categories

- News From Haomei (319)

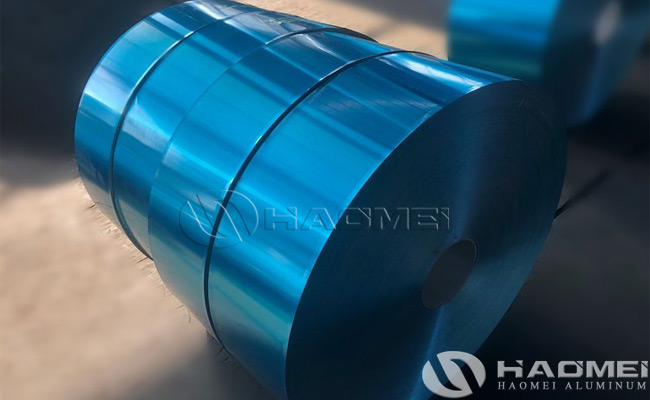

Blue hydrophilic coating aluminum foil is formed by hydrophilizing the surface of plain aluminum foil for making air conditioner fin stock. Blue hydrophilic aluminum foil is the most common material used for hydrophilic aluminum fin stocks. The second is gold hydrophilic coated aluminum foil. In addition to the chemical composition, mechanical properties and geometric dimensions required for hydrophilic coated aluminum foil, it should also have good sheet and coating properties.

For making blue hydrophilic coating aluminum foil, aluminium foil manufacturers need to have professional hydrophilic coating process line. The function of the coating process is to perform functional coating on the surface of the air conditioning aluminum foil. The main factors affecting the surface quality of the air conditioning hydrophilic aluminum foil in the coating process are the quality of coatings and pre-treatment agents, process layout, pre-treatment temperature and time, coating thickness control, coating drying temperature and time. The influence of coatings and pre-treatment agents on coating performance is decisive. Without good pre-treatment agents and coatings, it is impossible to produce high-quality coated foils. In addition, the selection of coatings and pre-treatment agents is related to coating processing equipment. Adaptation, not beyond the capabilities of the device. The use of coatings and treatments also varies with the coating process. Generally speaking, the more complex the coating process and the more processes, the better the surface coating performance of the hydrophilic coating aluminium foil.

Under certain conditions of coating, pre-treatment agent and process flow, coating performance mainly depends on the control of coating process parameters. The main points are as follows:

1, The temperature and time of the pretreatment are properly controlled to ensure that the surface of the blue hydrophilic coating aluminum foil is clean and free of oil stains.

2, Ensure that the coating roller and coating equipment are in good condition to obtain a uniform coating film with a certain thickness.

3, Appropriate curing temperature and time of the coating film to ensure good and uniform curing of the coating film.

4, It is required that the machine column has a certain installed level to ensure that the required process conditions are met.