Categories

- News From Haomei (323)

Aluminum foil for lamination of flexible packaging has the features of good mechanical strength, light-shielding, moisture-proof and waterproof. In addition, compared with other packaging material, aluminum foil base material has light weight, metallic luster, strong reflection ability to light, not easy to be corroded, good barrier property, airtight, no thermal adhesion and fragrance retention. Laminated aluminum foil for flexible packaging can be used in food, medicine, pesticides, chemicals, mechanical and electrical products. In the food and pharmaceutical industries, such as blisters, packaging bags, cheese pack, butter pack, yogurt lids and the like.

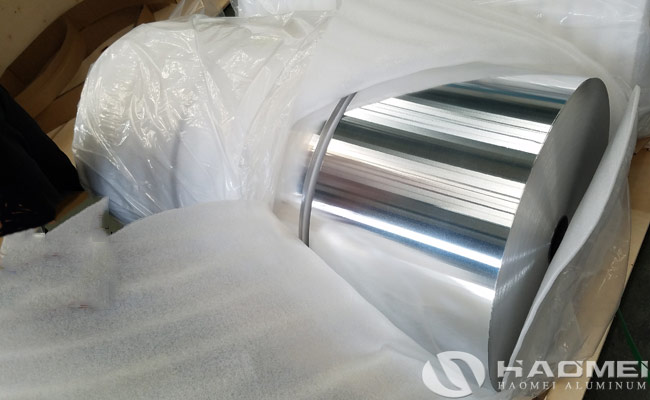

As used for flexible packaging, the first consideration is the barrier properties of the packaging materials because of the good barrier properties stand for long shelf life and better quality assurance. Currently, in all food packaging materials, aluminum foil for flexible packaging has the best barrier properties(followed by some polymer plastics, such as EVOH, PVDC, etc). So the most common is always to laminate a layer of aluminum foil in the middle of two layers of plastic film to improve the barrier properties. The aluminum foil used in lamination is 8011, usually the tamper is soft, the thickness is 0.02-0.1mm.

The aluminum foil for lamination composite film is two or more materials, combined by one or more compounding processes, thus forming a functional composite package. Generally, it can be divided into a base layer, a functional layer and a heat seal layer. The base layer mainly plays the role of beauty, printing and moisture resistance. Such as BOPP, BOPET, BOPA, MT, KOP, KPET and so on. The functional layer mainly functions as a barrier, and is protected from light, such as VMPET, AL, EVOH, PVDC, and the like. The heat seal layer is in direct contact with the packaged goods, and has the functions of adaptability, permeability resistance, good heat sealability, transparency, and opening properties, such as LDPE, LLDPE, MLLDPE, CPP, VMCPP, EVA, EAA, E- MAA, EMA, EBA, etc.