Categories

- News From Haomei (311)

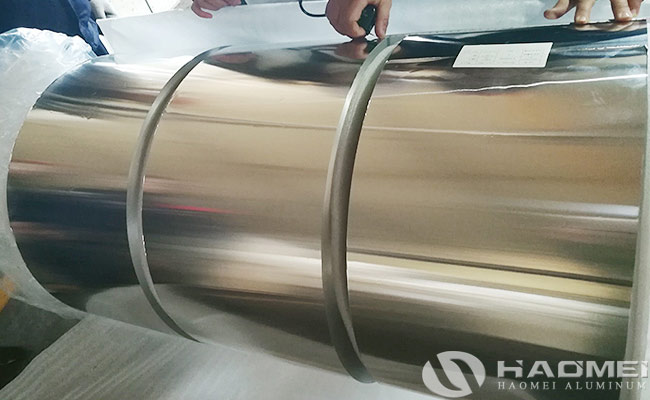

The aluminum foil roll manufacturers with rich experience have strict test and requirements on the pinhole number, thickness and edge burr of aluminum foil. Haomei Aluminum has introduced advanced production equipment to ensure the flatness of the aluminum foil roll, the surface is clean, uniform in color, without spots, smooth and without pinholes. The produced aluminium foil roll product has excellent moisture resistance, shading and barrier performance; non-toxic and tasteless, safe and hygienic.

Aluminum foil roll should be wrapped tightly, the end surface should be flush and clean, the edge is smooth, the foil surface is uniform in color, no streaks, no hole pin hole, the end face is neat and burr-free, and the thickness deviation range is small. The edge of the aluminum foil roll raw material does not interfere with burrs, bumps and other defects, and the surface must not be scratched and been corrosion.

When the aluminum foil roll material is packaged as a medicine, pinholes are not allowed, and the number and size of the aluminum foil pinholes are an important indicator of the standard of the medicine packaging materials. The number of pinholes in medicinal aluminum foil does not meet the requirements for use. The number of pinholes in the aluminum foil roll is a penetrating defect, which seriously affects the barrier property of the aluminum foil, especially on the outer packaging of the medicine, and it is easy to let oxygen, water vapor and light penetrate and the effect is lowered. When testing the number of pinholes in food and pharmaceutical packaging aluminum foil, it is still necessary for aluminum foil roll manufacturers to use a laboratory instrument that meets the standard requirements to complete the test.