Categories

- News From Haomei (315)

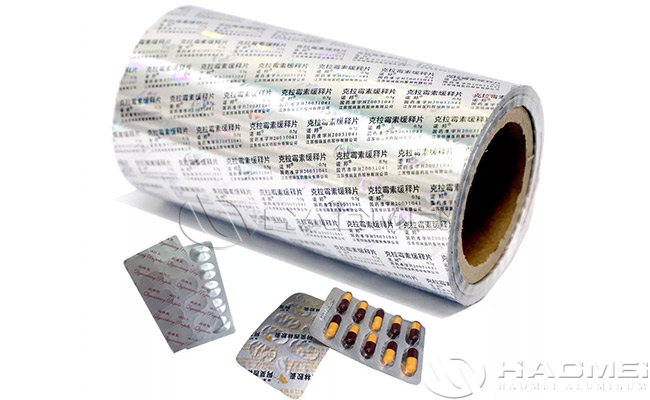

Aluminum foil for capsule packaging is a specially designed aluminum foil material, which is usually used for capsule packaging of medicines, health products and foods. Its main purpose is to provide effective protection and ensure the stability and safety of the product. Capsules packaging aluminum foil is mostly made of 8011-H18 aluminum foil and 8011-O aluminum foil. 8011 aluminum foil contains Mn and Mg elements, and has high strength and corrosion resistance. The general thickness is 0.016-0.04mm.

Features of aluminum foil for capsules packaging:

– Good barrier properties:

It can effectively block oxygen, moisture and light, prevent oxidation, deliquescence and deterioration of drugs in capsules, and extend the shelf life of drugs.

– Strong chemical stability:

Aluminum foil material will not react chemically with drugs in the package, ensuring the safety and effectiveness of drugs.

– Light weight:

Compared with other packaging materials, medicine aluminum foil is light in weight, convenient for transportation and carrying of drugs, and can reduce logistics costs.

– Good printability:

The surface of aluminum foil can be printed in a variety of ways, which is convenient for marking drug names, ingredients, usage methods, production dates, expiration dates and other information, so that consumers can understand the product.

– Easy to process and shape:

It has good plasticity and ductility, and can be easily processed into various shapes and sizes to meet different capsule packaging needs.

– Good environmental protection:

Aluminum foil materials can be recycled and reused, reducing resource waste and meeting environmental protection requirements.

Production process of aluminium foil for capsules packaging:

– Blank inspection:

Control quality from the source, strictly inspect blanks, and ensure that the raw materials meet pharmaceutical standards.

– Rolling:

Through processes such as blank rolling, open center rolling, and coil rolling, the aluminum ingot is processed into aluminum foil of the required thickness. During the rolling process, the surface quality is controlled by cleaning the rollers and controlling the roughness, selecting rolling oil, reducing the viscosity of the rolling oil, and controlling the running speed of the machine.

– Slitting:

The rolled aluminum foil rolls are slit according to the specified size to ensure that the edges of the aluminum foil rolls are neat during slitting, and there are no quality problems such as ruffles.

– Annealing:

Control the annealing time and temperature according to the performance requirements of the medicine foil to ensure clean degreasing and improve the performance of the aluminum foil.

– Composite, printing, and gluing:

Composite aluminum foil with polyethylene (PE), polypropylene (PP), polyester (PET) and other materials to enhance its strength, wear resistance and heat sealing performance, and then print and gluing the surface of the aluminum foil to meet the functional and aesthetic requirements of the capsule packaging.