Product Categories

- Dairy & yogurt pack (8)

- Pharmaceutical Pack (13)

- Food & beverage pack (9)

- Pure aluminum foil (7)

- Industrial Aluminum Foil (5)

PTP aluminum foil has moisture-proof, light proof, oxygen resistant properties, heat resistance, low temperature resistance and corrosion resistance, making it suitable for high-speed automated packaging in various environments.

PTP aluminum foils can be available in plain foil (No printing), Printed foil (one-sided printing, two-sided printing, single-color print, double color printing, polychrome printing, color foil (one-sided golden color, two-sided golden color, green bottom color, each kind of colored bottom color), forgery-proof (stealth writing, design, positive and negative printing), while single side or double sides printing assure better appearance upon request.

Printing aluminum foil, non-printing foil.

Thickness: 0.024 mm – 0.030 mm

Width: 80mm – 1000mm

Winding diameter: 275mm – 500mm

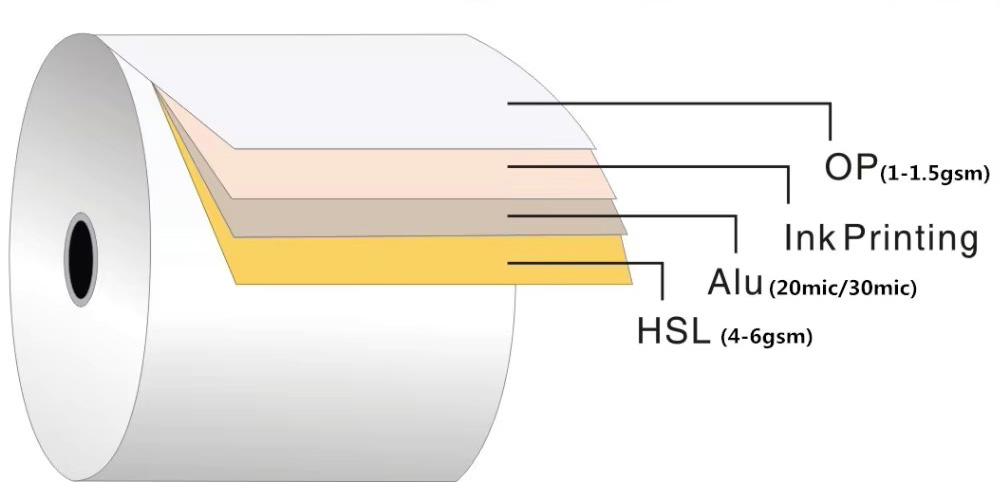

| Item | op al hsl Aluminium Foil for Blister Pack |

| Material | OP,AL,VC(HSL) |

| Alloy | 8011 |

| Width | 50mm-900mm |

| Thickness | 20 micron/25 micron/30 micron |

| Length | 1000-2000m (according to different requirement) |

| Roll ID | 76mm |

| Temper | H,O |

OP/Printing ink/Alu/VC

HSL seal with PVC, OP outside, printing on OP side

OP/AL 20-40μ(H)/VC and OP/AL 20-40μ(O)/VC

| OP(1-2gsm) | AL foil 20um | HSL(4-8gsm) |

| OP(1-2gsm) | AL foil 25um | HSL(4-8gsm) |

| OP(1-2gsm) | AL foil 30um | HSL(4-8gsm) |

It has the properties of oxygen resistance, light avoidance, and moisture-proof, easy to puncture, easy to take medicine, clean surface, uniform color, no spot, smooth and no pinhole.

– Excellent sealing strength with PVC, PVC/PVDC, PET, PP, PE and high-barrier base webs

– Primer systems for online and offline printing, easy printing for water-base and UV inks

– Perfect printing, no fading after sealing

– According to customer requirement: single side, double sides printing

– Sealing at low temperature, good for medicine and high speed processing

– High barrier against moisture, oxygen, other gases, light and UV lights.

Usually seal with cold aluminum or PVC, PVDC, used in blister packing for medicine purpose of tablets, pills, capsules, etc as well as candies.

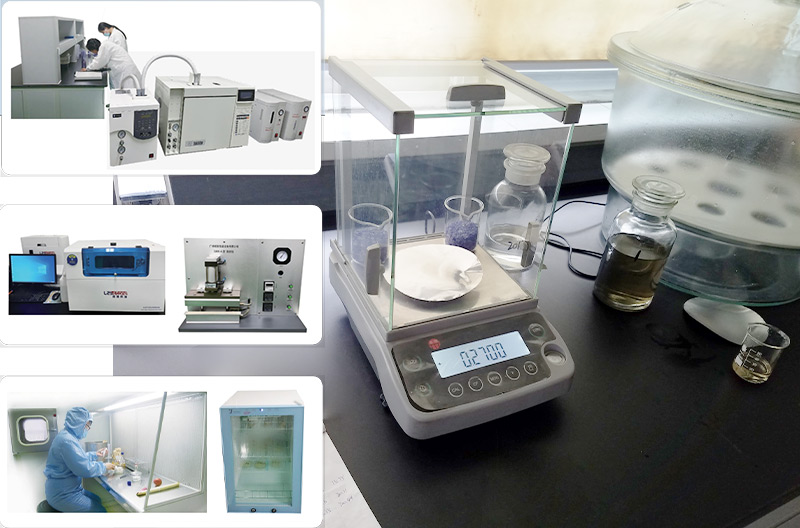

HaoMei Aluminum packaging has domestic technology leading six-roll calendering production line, “class D” purification production workshop; Annual output of 25,000 tons;

Select high quality imported raw materials, pay attention to every detail of production, to provide the most cost-effective packaging materials for pharmaceutical companies.

The laboratory is equipped with good performance of electronic analysis balance, high pressure steam sterilization pot, heat sealing instrument, oxygen penetration tester, meteorological chromatograph, electronic tensile testing machine and other testing equipment.

HaoMei packaging is in strict accordance with the primary pharmaceutical packaging material standard YBB00212005- 2015, ISO9001 quality recognition system, taking into account the requirements of GMP management department of drug manufacturing enterprises and establish a relatively perfect quality management and testing system, with a number of high-quality professional and technical personnel and advanced testing equipment, to provide a strong guarantee for the quality of products.