категории

- Новости От Haomei (325)

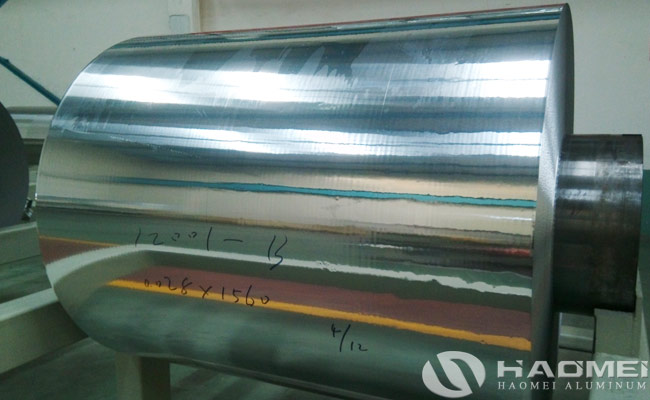

Haomei продукция алюминиевая фольга 50 микрон с высоким качеством, быстрая доставка, заводская цена, искреннее обслуживание и высокая производительность. Haomei Aluminium имеет несколько передовых оборудования для производства алюминиевой фольги с двойным нулем., который был признан в отрасли за его целостность, прочность и качество продукции. Поставляемая алюминиевая фольга с двойным нулем была хорошо принята большинством требовательных объектов.. Имеет высокую твердость, хорошая несущая способность, и относительно хороший эффект штамповки. Очень безопасно и гигиенично использовать фольгу для упаковки пищевых продуктов.. Haomei Aluminium — профессиональный производитель алюминиевой фольги.. Качество и производительность продукции стабильны и надежны. черного провода нет, нет яркой линии, нет обскура, Есть много преимуществ, высокое качество и низкая цена.

Алюминиевая фольга 50 Микрон относится к высококачественной алюминиевой фольге с двойным нулем толщиной около 0,005 мм и имеет широкую рыночную перспективу., и более 80% продукции из алюминиевой фольги будет экспортироваться во все части мира. А алюминиевая фольга продукты широко используются в упаковке пищевых продуктов, сигаретная упаковка, медицинская упаковка, аэрокосмический, гибкая упаковка, радиаторы, литиевые батареи, электролитические конденсаторы, кондиционеры, и т.д.

Алюминиевую фольгу можно производить небольшой толщины. 0.0025 мм и шириной 1800 мм при использовании ленточного метода производства. Прокат алюминиевой фольги – это безрулонная прокатка., а валки всегда находятся в упруго-сплющенном состоянии. Толщина алюминиевая фольга 50 микрон можно контролировать, регулируя силу прокатки, скорость прокатки и контроль натяжения во время прокатки. При черновой прокатке, сила прокатки используется для контроля толщины алюминиевой фольги; во время финишной прокатки, толщина алюминиевой фольги уменьшается по мере увеличения скорости прокатки; тем больше напряжение, чем меньше толщина; во избежание фрагментации, напряжение обычно выбирают как 0.2 к 0.4 условного предела текучестиσ0,2. При низкоскоростной прокатке, “густое масло” или “жидкое масло” часто добавляется в смазку для регулирования толщины прокатки алюминиевой фольги.. Смазка и состояние рулона имеют очень важное влияние на качество фольги.. Заготовка алюминиевой фольги изготавливается из холоднокатаного алюминиевого рулона., который обычно предварительно отжигают при 340-480°C., и его толщина 0.4-0.7 мм. Скорость деформации проката при прокатке составляет около 50%, а общая скорость деформации может достигать более 95%. Готовая алюминиевая фольга толщиной менее 0,01~0,02 мм должна быть прокатана в два листа..