categorías

- Noticias de Haomei (325)

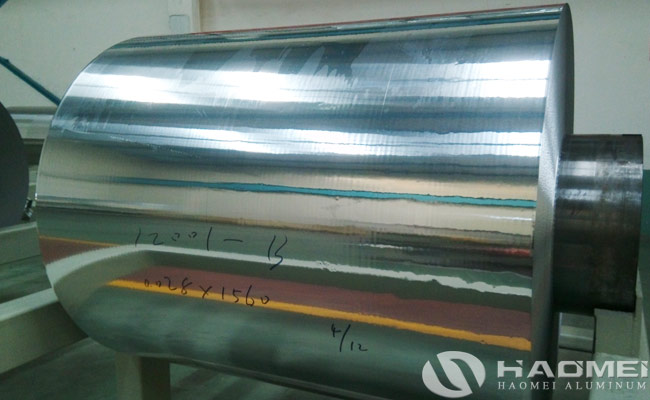

productos Haomei papel de aluminio 50 micrón con alta calidad, entrega rápida, precio de fábrica, servicio sincero y alto desempeño. El aluminio Haomei tiene varios equipos avanzados de producción de papel de aluminio de doble cero, que ha sido reconocido por la industria por su integridad, fuerza y calidad del producto. El papel de aluminio de doble cero suministrado ha sido bien recibido por la mayoría de los objetos exigentes. Tiene alta dureza, Buena carga, y efecto de estampado relativamente bueno. Es muy seguro e higiénico usarlo como papel de envasado de alimentos. El aluminio de Haomei es un fabricante profesional de aluminio de aluminio. La calidad y el rendimiento del producto son estables y confiables. No hay alambre negro, Sin línea brillante, sin agujero de alfiler, Hay muchas ventajas, alta calidad y bajo precio.

La lámina de aluminio 50 Micron pertenece a una lámina de aluminio de doble cero de alta gama con un grosor de aproximadamente 0.005 mm tiene una amplia perspectiva del mercado, y más de 80% de los productos de aluminio se exportarán a todas las partes del mundo. los papel de aluminio Los productos se utilizan ampliamente en el embalaje de alimentos, embalaje de cigarrillos, embalaje médico, aeroespacial, embalaje flexible, radiadores, baterías de litio, condensadores electrolíticos, acondicionadores de aire, etc..

La lámina de aluminio se puede producir con un pequeño grosor de 0.0025 mm y un ancho de 1800 mm utilizando el método de producción de cinta. El rodillo de aluminio de aluminio es una rodadura sin rollo, y los rollos siempre están en un estado aplanado elástico. El grosor del papel de aluminio 50 micrón se puede controlar ajustando la fuerza rodante, Velocidad de rodadura y tensión de control durante la rodadura. Durante el rodaje rugoso, La fuerza de rodadura se usa para controlar el grosor de la lámina de aluminio; Durante el final de la rodadura, El grosor de la lámina de aluminio disminuye a medida que aumenta la velocidad de rodadura; cuanto mayor es la tensión, cuanto más pequeño es el grosor; Para prevenir la fragmentación, la tensión generalmente se selecciona como 0.2 a 0.4 de resistencia de rendimiento condicional dσ0.2. En rodar a baja velocidad, “aceite grueso” o “aceite delgado” a menudo se agrega al lubricante para ajustar el grosor de rodadura de la lámina de aluminio. Lubricante y el estado de rollo tienen una influencia muy importante en la calidad de la lámina. El en blanco de aluminio proviene de la bobina de aluminio enrollada, que generalmente se recopina previamente a 340-480 ° C, y su grosor es 0.4-0.7 mm. La tasa de deformación de pase durante el rodamiento se trata de 50%, y la tasa de deformación total puede alcanzar más que 95%. La lámina de aluminio terminada cuyo grosor es inferior a 0.01 ~ 0.02 mm debe rodarse y enrollar la doble hoja.