Categories

- News From Haomei (321)

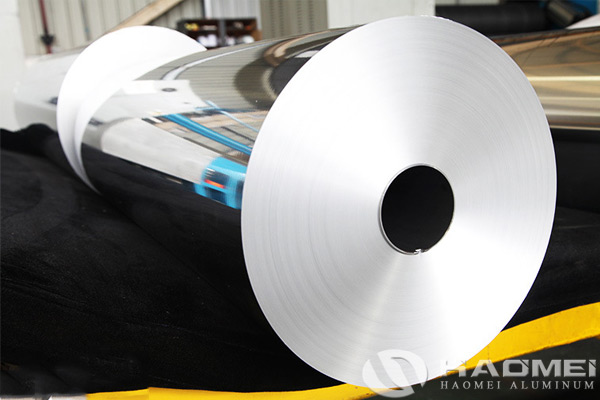

Food grade aluminium foil paper is a kind of aluminum foil material specially used for food packaging. Food-grade aluminum foil paper complies with food safety standards and can be directly or indirectly contacted with food. It is mainly used for food packaging, such as making cooking pouches, multi-layer composite pouches, aseptic boxes, etc., as well as being used as lidding material for food, tray box making, wrapping material, etc.

The food grade aluminium foil paper specification is:

Alloy: 1235, 3003, 8011, 8021, 8079

Processing thickness: 0.016-0.5mm.

Processing width: 10-1600mm.

Delivery period: 7-35 days.

Uses: food packaging foil, pharmaceutical packaging foil, milk cap material, lunch box material, container foil, household foil, barbecue foil, beer sealing foil, bottle cap material and so on.

Executable standards: national standard, American standard, European standard, Russian standard, Japanese standard, etc.

Characteristics and advantages of food grade foil paper:

– High temperature resistance: food grade aluminum foil has excellent high temperature resistance, can withstand high temperature baking without deformation, to protect the food from damage due to high temperature.

– Antioxidant: Aluminum foil can effectively prevent oxygen from entering the package, thus prolonging the shelf life of the food and preventing the food from oxidizing and deteriorating.

– Anti-bacteria and moisture barrier: Aluminum foil has anti-bacteria ability on the surface, and also has excellent moisture barrier performance, which can avoid moisture, deterioration and mildew of the food inside the package.

– Anti-ultraviolet ray: food-grade aluminum foil can also effectively prevent the harm of ultraviolet rays on food, to ensure the quality and safety of food.

– Recyclability: Aluminum foil material has good recyclability and meets the requirements of environmental protection.

Production and Quality Control of food grade aluminium foil paper:

– Production process: The production of food-grade aluminum foil needs to go through several processes, including melting, casting, rolling and finishing. During the production process, the quality of raw materials and production process parameters need to be strictly controlled to ensure the food safety and performance of aluminum foil.

– Quality control: The quality control of food-grade aluminum foil includes raw material inspection, production process control, finished product inspection and many other aspects. Through strict inspection and testing, it can be ensured that the chemical composition, physical properties and hygiene indexes of aluminum foil meet the food safety standards.

With the rapid development of the food industry and the improvement of consumers’ requirements for food safety and quality, the market demand for food-grade aluminum foil is increasing. The size of the global aluminum foil packaging market continues to grow, of which food packaging is one of the main application areas of aluminum foil. Food-grade aluminum foil is widely used in the packaging of various types of food, such as meat, fish, vegetables, fruits, dairy products, and pastries. In addition, aluminum foil is also commonly used to make various food containers and tableware, such as aluminum foil lunch boxes and aluminum foil paper cups.

To sum up, food grade aluminium foil paper has a variety of excellent characteristics and a wide range of applications. In the food packaging industry, aluminum foil materials play an increasingly important role.