Categories

- News From Haomei (311)

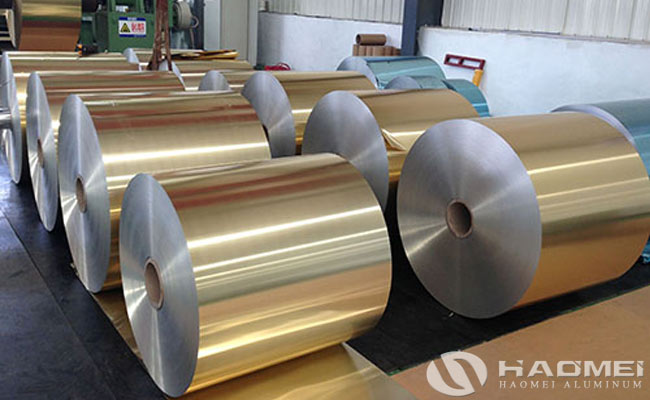

Food grade aluminum foil is mainly used for food and quasi-food packaging, the thickness is 0.015, 0.012, 0.009, 0.007 microns, and the aluminum alloys are 1145, 1235, 1100, 3003, 8011, 8079 and so on. The performance requirements for food grade aluminium foil are strict because it is connected to the food directly.

Pinholes are the most important indicator for aluminum foil for food, especially for 0.02 and 0.015 micron thick aluminum foil. Since the aluminium foil is the main packaging material, there are no or few composite layers, and it is required for no pinholes. The 0.009 and 0.007 micron thick aluminum foil is usually used as one of the composite layers, and the number of pinholes is controlled at 30 per m2. The food packing aluminum foil plays major sealing role in the composite material, and the composite layer plays a supporting role. The pinhole-free aluminum foil can be considered to have zero gas permeability and water permeability. The food packaging material with aluminum foil is high grades, the gas and water permeability performance is much better. The light shielding property of the aluminum foil is also related to the pinhole distribution. Now the high quality aluminum foil can achieve 0.013mm without pinholes, there are only a few pinholes for 0.009mm thick aluminum foil, which indicates that the aluminum foil is much less breathable than the various films. The barrier effect of aluminum foil on radiation is much greater than that of film and paper. For visible light, pinhole free aluminum foil is completely opaque.

Non-toxic and non-polluting is one of the main requirements of food grade aluminum foil, the surface is clean and oil-free, and the aluminum foil composition meets the requirements of food packaging standards. At present, rolling oils and related media to produce aluminum foils for food are required not toxic and comply with food-grade hygiene standards (low aromatics 1%, low sulfur 5 ppm).