Categories

- News From Haomei (326)

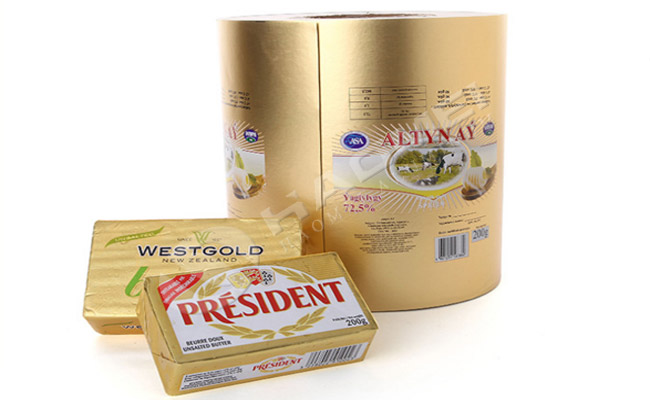

Aluminum cheese pack foil is widely used in cheese packaging because of its high reflectivity to heat and light, good isolation, strong protection, impermeability to gas and water vapor, which can prevent the cheese from drowning and gasification, and is not vulnerable to bacteria and insects. Cheese is a kind of dairy product with high nutritional value, it has its own unique characteristics, such as size, shape, color, ripening conditions, flavor, coating, surface mildew, which put forward high requirements for cheese packaging material, not only to ensure the quality of different cheese, but also to extend shelf life as long as possible.

The packaging of cheese products seriously affects the performance, cheese packaging foil materials should not contain harmful ingredients to ensure food safety. Cheese packaging foil materials also require processing characteristics and gas barrier properties to meet the needs of the product. Processing characteristics include thermoformability, heat sealability, mechanical stability, hot stretchability, machine walkability, and ecological and economic constraints. Gas barrier is mainly to prevent the penetration of oxygen, carbon dioxide, nitrogen and water vapor. Usually aluminum cheese packaging foil materials first require blocking oxygen to prevent mold growth. Secondly, some mature cheeses pack foil are required to block the water vapor in order to avoid water loss and cause quality loss.