Categories

- News From Haomei (323)

Commonly used alloy for aluminum foil for sealing is 8011-O aluminum foil. Uses: After printing or painting, it is used for packaging milk products such as fresh milk and yogurt. For medicinal and food-grade aluminum foil packaging, the quality is reflected in the heat-sealing strength of the aluminum foil packaging to a large extent, which is also one of the important indicators to ensure the safety of the product without being polluted or leaked.

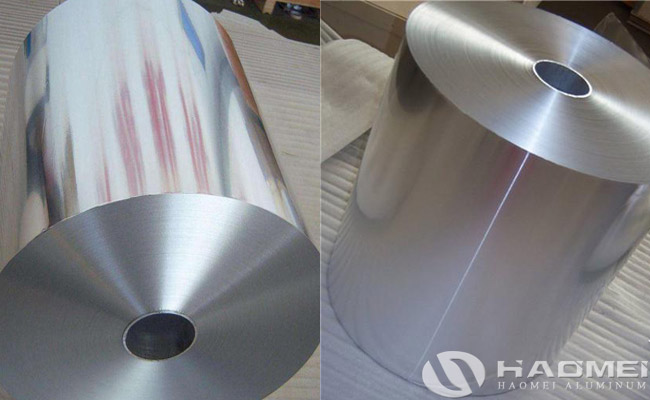

8011-O aluminum foil for sealing as few pinholes, good barrier properties, heat sealability and tensile strength, and the product has clean oil removal and clean surface. The product reaches food grade, and can be cooked at high temperature, safe and sanitary. Surface quality of aluminum foil for hot sealing:

A, There is no stickiness, blistering, yellow oil spots and tearing on the surface of the aluminum foil after annealing;

B, The surface of the aluminum foil has no bright spots, plaques, clean marks and black lines on the grinding wheel;

C, The surface of the aluminum foil is clean, free of cracks, wrinkles, scratches, roller prints, twill, etc.;

D, The surface of the finished aluminum foil is flat.

Haomei Aluminum is a large-scale aluminum foil for sealing raw material manufacturer. The 8011 aluminum foil and 3003 aluminum foil substrates produced by the company are the source of various sealing aluminum foil raw materials. 8011 aluminum foil has O, H22, H24, etc., with a thickness ranging from 0.02-0.055mm and a width ranging from 100-1600mm.