Categories

- News From Haomei (323)

Aluminium barrier foil film is an important packaging material, and the purity of packaging aluminum foil is above 99.5%. Aluminum foil have good mechanical strength, light weight, no thermal adhesion, metallic luster, good shading, strong reflection ability to light, not easy to be corroded, good barrier properties, moisture and water resistance, strong air tightness, and Fragrance retention. So the aluminum barrier foil is widely applied to medical packaging substrates, high-temperature cooking food packaging, barrier packaging (flavors, spices) and electromagnetic shielding packaging, etc.

The aluminium barrier foil is actually an aluminum foil composite film material structure with great barrier performance and composite strength. With the development of society and the improvement of people’s living standards, the commodity economy is becoming more and more developed. In order to improve the circulation cycle and shelf life of commodities, the role of commodity packaging is becoming more and more important, especially for food , Medicines, cosmetics, detergents and other products with high quality requirements, aluminium foil packaging materials with high barrier properties is often the most effective means. At present, in the field of flexible packaging, barrier film materials such as co-extruded film containing EVOH resin, coated PVDC film, vapor-deposited oxide film, aluminum foil, etc. can be selected to meet the packaging requirements of the above products through one (or multiple) compounding.

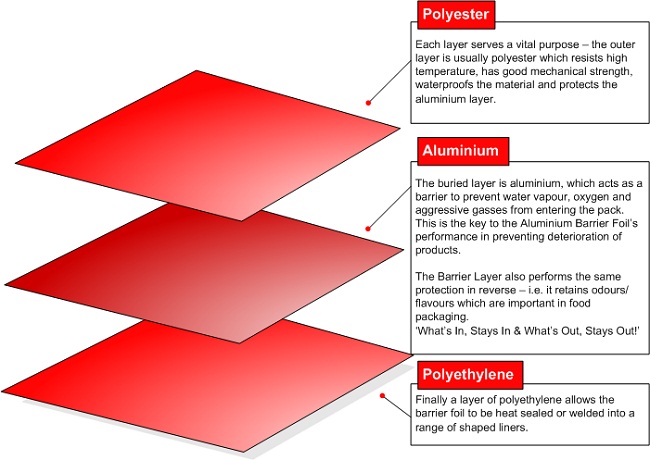

As the aluminum foil used on flexible plastic packaging, it has outstanding barrier properties. Under the premise of sufficient thickness of aluminum foil, it can basically completely block gas and moisture. Therefore, aluminum foil is the more commonly used barrier material in flexible plastic packaging base film. Aluminium barrier foil film has high peel strength and high barrier properties, innovative in structure and technology, and has certain cost advantages. Surface layer has high tensile strength, and its excellent transparency can fully show fine printing. The high-barrier aluminium foil layer is a barrier layer, which plays a key role in maintaining the quality and fragrance of the package contents. The inner PE (or CPP) film layer is a heat-sealing layer, which is a material that directly contacts the contents of the package.