Categories

- News From Haomei (325)

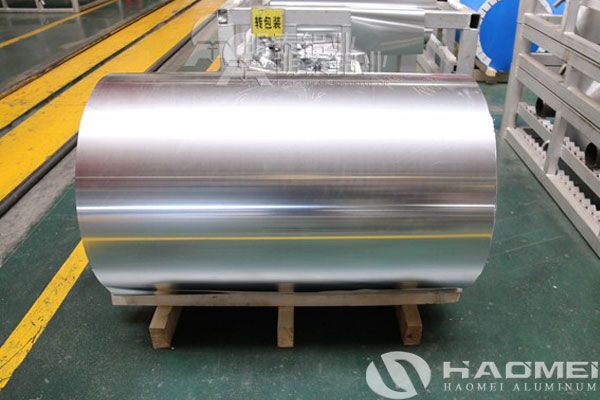

Aluminum barrier packaging foil is a kind of flexible packaging material with excellent vapour barrier and moisture barrier. In current packaging, almost all packaging that requires light-tightness or high barrier properties uses aluminum foil as a grouping layer. The commonly used materials are 8011 aluminum foil, 1235 aluminum foil and 8079 aluminum foil. Aluminum barrier foil has superior high barrier properties, moisture-proof, heat-sealability and strong sealing ability.

High barrier aluminum packaging foil should not break easily when folded and must have good resistance. The purchased aluminum barrier foil should be kept in a dry state, and the storage time should not be too long. It should be used as soon as possible to prevent it from absorbing moisture and oxidation.

High barrier aluminum foil is a metal. Aluminum barrier packaging foil use soft aluminum foil with a thickness of 9 μm (also 7 μm). It has excellent moisture resistance, gas barrier and light barrier properties. Provided there are no mechanical damage and pinholes, it is completely impermeable to moisture, air and light and is extremely heat and oil resistant. Therefore, the composite packaging bag containing aluminum barrier foil has the functions of complete sealing, high aroma preservation, high oil resistance and high temperature resistance.

It should be a good barrier material, but if there are pinholes, its barrier performance will be greatly reduced, gas and light will directly penetrate directly, and its contents will also change quickly. Generally, the thicker the foil, the lower the number of pinholes. For example, the thickness of 7μm aluminum foil should be less than 200 holes per square meter: for 9μm aluminum foil, the number of pinholes should be less than 100 holes/square meter. No matter how thick the aluminum foil is, the diameter of the pinhole should not be larger than 20μm.

There is no oil and dust on the surface, and the surface tension should be high, which should be greater than 72mN/m. An easy way to do this is to check with distilled water, which should fully wet the surface of the aluminum foil. If the oil on the surface of the aluminum foil is serious, it will affect the composite color fastness of the aluminum foil and other materials, especially after high-temperature cooking bags, delamination will occur.