Categories

- News From Haomei (320)

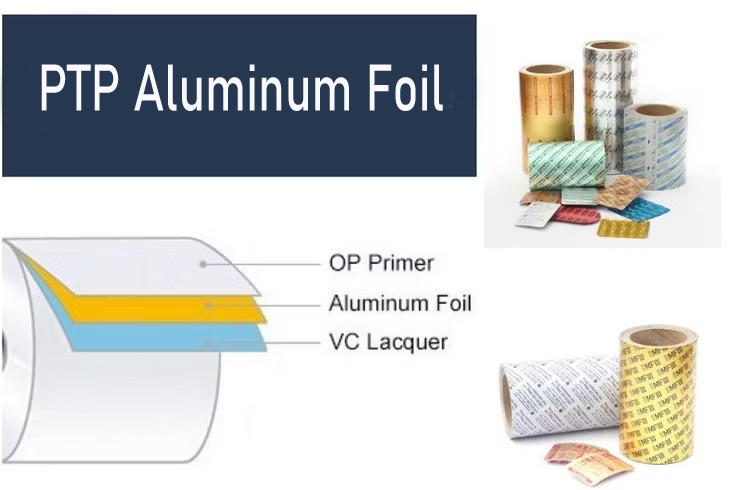

OP/ALU/VC aluminum lidding foil is a composite material specifically designed for pharmaceutical blister packaging. Its structure consists of a protective layer (OP), an aluminum foil layer (ALU), and an adhesive layer (VC). OP/ALU/VC aluminum foil possesses high barrier properties, heat-sealability, easy printability, and good mechanical properties, effectively protecting the contents and meeting the needs of automated packaging.

Structural composition of OP/ALU/VC aluminum blister lidding foil:

– OP (OPA) Layer:

Typically made of polyester film (such as PET), with a thickness of 25-30μm. It provides surface protection with good mechanical strength and abrasion resistance, preventing scratches or contamination of the aluminum foil layer. It also serves as a printing substrate, supporting high-precision pattern and text printing.

– ALU (Al) Layer:

The aluminum foil layer, made of high-purity aluminum foil such as 8011 alloy, with a thickness of generally 20-50μm. It is the core barrier layer. Aluminum foil has excellent barrier properties, effectively blocking oxygen, moisture, and light, protecting the medicine from external environmental influences and extending its shelf life.

– VC Layer:

This is a heat-sealable coating, typically using polyurethane adhesive, with a coating amount of approximately 4±0.5g/m². It is heat-sealed with rigid plastic sheets such as PVC and PVDC to form a sealed package. It is non-toxic, odorless, and meets food and pharmaceutical hygiene standards; the coating is uniform, and the heat-sealing strength is high, ensuring packaging airtightness.

– Specifications:

Width generally does not exceed 800mm, total thickness is 0.09-0.10mm, and inner diameter is 76mm.

Core performance of OP/ALU/VC aluminum lidding foil:

– High barrier properties:

The aluminum foil layer has extremely low permeability to oxygen and water vapor (e.g., oxygen permeability ≤0.5cm³/(m²·24h·0.1MPa)), suitable for packaging humidity- and oxygen-sensitive pharmaceuticals (such as antibiotics and vitamins) and foods (such as chocolate and candy).

– Heat-sealing capability:

The VC layer and PVC/PVDC rigid sheet are heat-sealed at 120-180℃ to form a strong bond with a sealing strength ≥8N/15mm, preventing leakage or contamination of the contents.

– Printability:

The OP layer of PTP aluminum foil supports monochrome and multicolor printing, allowing for the printing of drug information, brand logos, or anti-counterfeiting patterns, enhancing packaging aesthetics and readability.

– Mechanical properties:

The aluminum foil layer provides the material with good tensile strength and puncture resistance, adapting to high-speed automated packaging equipment and reducing breakage rates during packaging.

OP/ALU/VC aluminum lidding foil offers high barrier properties, effectively blocking light, moisture, and oxygen, protecting drug quality; it has good heat-sealing properties with PVC, facilitating heat sealing with PVC blister packs; it also features wrinkle resistance and antibacterial properties, providing excellent protection for drugs. Primarily used in pharmaceutical packaging such as capsules, pills, and tablets, it is a commonly used capping material in pharmaceutical blister packaging (PTP). Through heat sealing with PVC blister packs, the drug is encapsulated within the blister pack, achieving both protection and convenient access.