الاقسام

- الأخبار من Haomei (325)

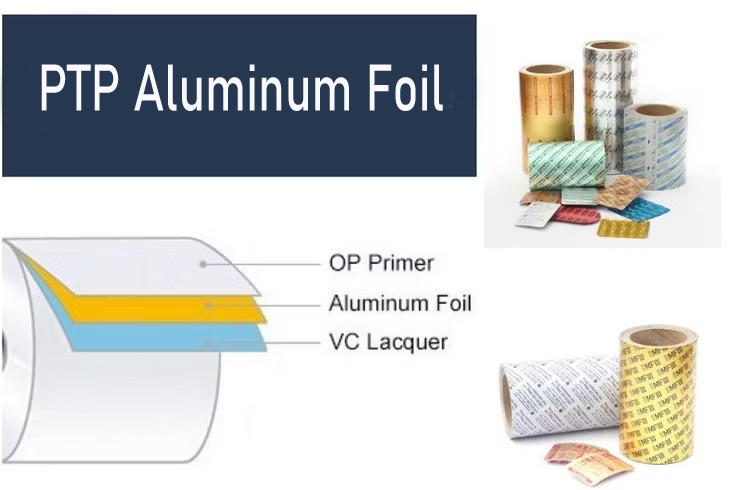

OP. هي مادة مركبة مصممة خصيصًا لتغليف الفقاعات الصيدلانية. يتكون هيكلها من طبقة واقية (OP), طبقة رقائق الألومنيوم (ألو), وطبقة لاصقة (VC). تمتلك رقائق الألومنيوم OP/ALU/VC خصائص حاجز عالية, الختم الحراري, سهولة الطباعة, وخصائص ميكانيكية جيدة, حماية المحتويات بشكل فعال وتلبية احتياجات التغليف الآلي.

التركيب الهيكلي لرقائق غطاء نفطة الألومنيوم OP/ALU/VC:

– OP (OPA) طبقة:

عادة ما تكون مصنوعة من فيلم البوليستر (مثل الحيوانات الأليفة), بسمك 25-30μm. إنه يوفر حماية للسطح مع قوة ميكانيكية جيدة ومقاومة للتآكل, منع الخدوش أو تلوث طبقة رقائق الألومنيوم. كما أنه بمثابة ركيزة الطباعة, دعم نمط عالي الدقة وطباعة النص.

– ألو (شركة) طبقة:

طبقة ورق الألمنيوم, مصنوعة من رقائق الألومنيوم عالية النقاء مثل 8011 أشابة, بسماكة عامة 20-50μm. إنها الطبقة الحاجزة الأساسية. تتميز رقائق الألومنيوم بخصائص حاجزة ممتازة, منع الأكسجين بشكل فعال, رطوبة, وضوء, حماية الدواء من التأثيرات البيئية الخارجية وإطالة مدة صلاحيته.

– أنت طبقة:

هذا طلاء قابل للغلق بالحرارة, عادة باستخدام لاصق البولي يوريثين, مع كمية طلاء تبلغ حوالي 4±0.5 جم/م². وهي مختومة بالحرارة باستخدام صفائح بلاستيكية صلبة مثل PVC وPVDC لتشكيل حزمة محكمة الغلق. إنه غير سامة, عديم الرائحة, ويلبي معايير النظافة الغذائية والصيدلانية; الطلاء موحد, وقوة الختم الحراري عالية, ضمان إحكام التعبئة والتغليف.

– مواصفات:

العرض عموما لا يتجاوز 800 ملم, السماكة الإجمالية 0.09-0.10 ملم, والقطر الداخلي 76 ملم.

الأداء الأساسي لرقائق الألومنيوم OP/ALU/VC:

– خصائص حاجز عالية:

تتميز طبقة رقائق الألومنيوم بنفاذية منخفضة للغاية للأكسجين وبخار الماء (على سبيل المثال, نفاذية الأكسجين .50.5cm³/(M² · 24H · 0.1MPa)), مناسبة لرطوبة التعبئة والتغليف- والأدوية الحساسة للأكسجين (مثل المضادات الحيوية والفيتامينات) والأطعمة (مثل الشوكولاتة والحلوى).

– القدرة على الختم الحراري:

طبقة VC و PVC / PVDC يتم غلق الصفائح الصلبة بالحرارة عند درجة حرارة 120-180 درجة مئوية لتكوين رابطة قوية بقوة إغلاق ≥8N/15mm, منع تسرب أو تلوث المحتويات.

– إمكانية الطباعة:

طبقة OP من رقائق الألومنيوم PTP يدعم الطباعة أحادية اللون ومتعددة الألوان, السماح بطباعة المعلومات الدوائية, شعارات العلامة التجارية, أو أنماط مكافحة التزييف, تعزيز جماليات التعبئة والتغليف وسهولة القراءة.

– الخصائص الميكانيكية:

توفر طبقة رقائق الألومنيوم للمادة قوة شد جيدة ومقاومة للثقب, التكيف مع معدات التعبئة والتغليف الآلية عالية السرعة وتقليل معدلات الكسر أثناء التعبئة.

OP. يوفر خصائص حاجز عالية, حجب الضوء بشكل فعال, رطوبة, والأكسجين, حماية جودة الدواء; لديها خصائص جيدة للختم الحراري مع PVC, تسهيل الختم الحراري باستخدام عبوات نفطة PVC; كما أنه يتميز بمقاومة التجاعيد وخصائص مضادة للبكتيريا, توفير حماية ممتازة للمخدرات. يستخدم في المقام الأول في عبوات الأدوية مثل الكبسولات, حبوب الدواء, وأقراص, إنها مادة تغطية شائعة الاستخدام في عبوات الفقاعات الصيدلانية (PTP). من خلال الختم الحراري باستخدام عبوات نفطة PVC, يتم تغليف الدواء داخل عبوة نفطة, تحقيق كل من الحماية وسهولة الوصول.