Kategorien

- Nachrichten aus Haomei (325)

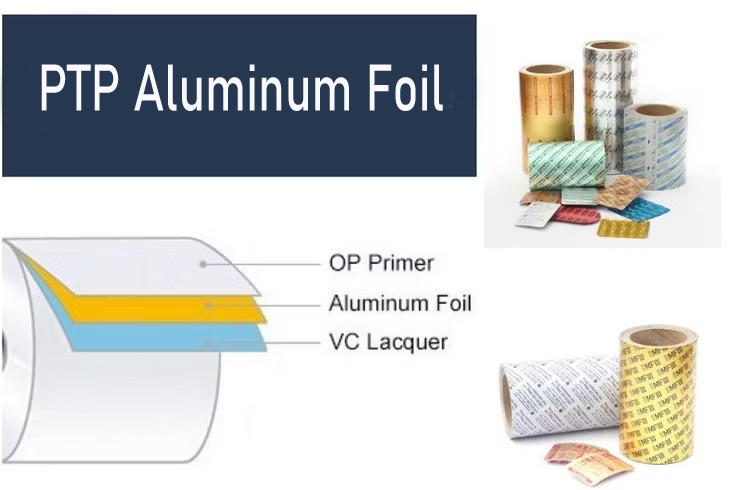

OP. ist ein Verbundmaterial, das speziell für pharmazeutische Blisterverpackungen entwickelt wurde. Seine Struktur besteht aus einer Schutzschicht (OP), eine Aluminiumfolienschicht (ALU), und eine Klebeschicht (VC). OP/ALU/VC-Aluminiumfolie verfügt über hohe Barriereeigenschaften, Heißsiegelbarkeit, einfache Bedruckbarkeit, und gute mechanische Eigenschaften, Wirksamer Schutz des Inhalts und Erfüllung der Anforderungen automatisierter Verpackung.

Strukturzusammensetzung der OP/ALU/VC-Aluminium-Blisterdeckelfolie:

– OP (OPA) Schicht:

Typischerweise aus Polyesterfolie (wie Haustier), mit einer Dicke von 25-30μm. Es bietet Oberflächenschutz mit guter mechanischer Festigkeit und Abriebfestigkeit, verhindert Kratzer oder Verunreinigungen der Aluminiumfolienschicht. Es dient auch als Druckträger, Unterstützung des hochpräzisen Muster- und Textdrucks.

– ALU (al) Schicht:

Die Aluminiumfolienschicht, aus hochreiner Aluminiumfolie wie z.B 8011 Legierung, mit einer Dicke von im Allgemeinen 20–50 μm. Es ist die Kernbarriereschicht. Aluminiumfolie verfügt über hervorragende Barriereeigenschaften, Sauerstoff effektiv blockieren, Feuchtigkeit, und Licht, das Arzneimittel vor äußeren Umwelteinflüssen zu schützen und seine Haltbarkeit zu verlängern.

– Sie schichten:

Hierbei handelt es sich um eine heißsiegelbare Beschichtung, Typischerweise wird Polyurethan-Kleber verwendet, mit einer Beschichtungsmenge von ca. 4±0,5g/m². Es wird mit starren Kunststofffolien wie PVC und PVDC heißversiegelt, um eine versiegelte Verpackung zu bilden. Es ist ungiftig, geruchlos, und erfüllt die Hygienestandards für Lebensmittel und Pharmazeutika; Die Beschichtung ist gleichmäßig, und die Heißsiegelfestigkeit ist hoch, Gewährleistung der Luftdichtheit der Verpackung.

– Technische Daten:

Die Breite beträgt im Allgemeinen nicht mehr als 800 mm, Die Gesamtdicke beträgt 0,09–0,10 mm, und der Innendurchmesser beträgt 76 mm.

Kernleistung der OP/ALU/VC-Aluminium-Abdeckfolie:

– Hohe Barriereeigenschaften:

Die Aluminiumfolienschicht weist eine äußerst geringe Durchlässigkeit für Sauerstoff und Wasserdampf auf (z.B., Sauerstoffdurchlässigkeit ≤0,5cm³/(m² · 24H · 0,1 MPa)), Geeignet für Verpackungsfeuchtigkeit- und sauerstoffempfindliche Arzneimittel (wie Antibiotika und Vitamine) und Lebensmittel (wie Schokolade und Süßigkeiten).

– Heißsiegelfähigkeit:

Die VC-Schicht und PVC / PVDC Starre Platten werden bei 120–180 °C heißversiegelt, um eine starke Verbindung mit einer Siegelfestigkeit von ≥8 N/15 mm zu bilden, verhindert ein Auslaufen oder eine Kontamination des Inhalts.

– Druckbarkeit:

Die OP-Schicht von PTP-Aluminiumfolie unterstützt Monochrom- und Mehrfarbendruck, Ermöglicht das Drucken von Arzneimittelinformationen, Markenlogos, oder Anti-Fälschungsmuster, Verbesserung der Verpackungsästhetik und Lesbarkeit.

– Mechanische Eigenschaften:

Die Aluminiumfolienschicht verleiht dem Material eine gute Zugfestigkeit und Durchstoßfestigkeit, Anpassung an automatisierte Hochgeschwindigkeitsverpackungsanlagen und Reduzierung der Bruchraten beim Verpacken.

OP. bietet hohe Barriereeigenschaften, effektiv licht blockieren, Feuchtigkeit, und Sauerstoff, Schutz der Arzneimittelqualität; Es verfügt über gute Heißsiegeleigenschaften mit PVC, erleichtert das Heißsiegeln mit PVC-Blisterpackungen; Es zeichnet sich außerdem durch Knitterfestigkeit und antibakterielle Eigenschaften aus, Bietet hervorragenden Schutz vor Medikamenten. Wird hauptsächlich in pharmazeutischen Verpackungen wie Kapseln verwendet, Pillen, und Tabletten, Es ist ein häufig verwendetes Verschlussmaterial in pharmazeutischen Blisterverpackungen (PTP). Durch Heißversiegelung mit PVC-Blisterpackungen, Das Medikament ist in der Blisterpackung eingekapselt, um sowohl Schutz als auch bequemen Zugang zu gewährleisten.