الاقسام

- الأخبار من Haomei (315)

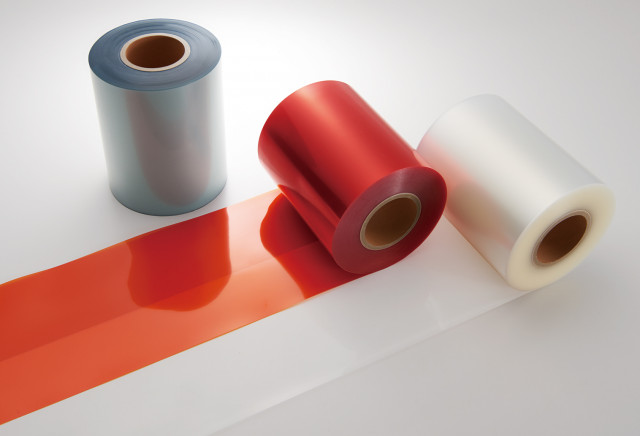

High barrier pharmal grade PVC/PVDC rigid film is a high-performance composite material designed for pharmaceutical blister packaging. من خلال الجمع بين قابلية تشكيل كلوريد البولي فينيل (PVC) وخاصية الحاجز المتطرف لكلوريد البولي فينيلدين (PVDC), يوفر حماية طويلة الأجل للأدوية التي تمتص الرطوبة وحساسية الأكسجين, ويستخدم على نطاق واسع في السيناريوهات مع متطلبات عالية للغاية للختم والاستقرار. Haomei provide PVC/PVDC rigid film with a coating amount of 40g/60g/90g/㎡, using BASF PVDC emulsion, and the oxygen barrier performance is more than 10 times that of PVC.

The structural design of high barrier pharmaceutical grade PVC/PVDC rigid film needs to take into account barrier performance, mechanical strength, sterilization compatibility and processing feasibility, and its core is a multi-layer composite system.

1. PVC layer (البولي فينيل كلورايد)

وظيفة: As a substrate, it provides basic mechanical strength and forming ability. فيلم PVC has good transparency and moderate barrier properties.

سمات: The PVC layer usually has good chemical resistance and processing performance, and is suitable for processing methods such as heat sealing and cold sealing.

2. PVDC layer (فلوريد البولي فينيلدين)

وظيفة: Provides excellent barrier properties, especially against water vapor and oxygen. PVDC is a high-performance polymer that can significantly improve the film’s ability to keep fresh.

سمات: The PVDC layer has low moisture and oxygen permeability, which can effectively extend the shelf life of the product.

3. طبقة لاصقة

وظيفة: Used to firmly combine the PVC layer and the PVDC layer to ensure the integrity and stability of the film during use.

سمات: The selection of the adhesive layer needs to take into account the compatibility with PVC and PVDC to ensure good bonding.

4. Surface treatment layer (optional)

وظيفة: Treat the outer surface of the film to improve printing performance, antistatic properties or other specific functional requirements.

سمات: Surface treatment can enhance the adhesion of the film and facilitate printing or coating.

ال PVC/PVDC film has ultra-high barrier performance:

Water vapor barrier rate is 5–15 times higher than that of ordinary PVC (WVTR <0.1 ز/(M² · 24H));

Oxygen barrier rate is more than 10 times higher (OTR <1.6 Cm³/(M² · 24H · 0.1MPa)).

Shelf life guarantee: In hot and humid environments (such as Southeast Asia), the shelf life of drugs can be extended from 3 months of ordinary PVC to more than 2 years to avoid moisture absorption and deterioration.

Features of high barrier pharma grade PVC/PVDC rigid film:

– أداء الحاجز الممتاز:

The combination of PVC (البولي فينيل كلورايد) وPVDC (فلوريد البولي فينيلدين) can effectively block water vapor, الأكسجين والضوء, protecting the stability and effectiveness of drugs.

– الاستقرار الكيميائي:

The film has good tolerance to a variety of chemicals and can effectively prevent the degradation of drug ingredients.

– خصائص ميكانيكية جيدة:

The hard film has high strength and tear resistance, suitable for use in production and transportation.

– الشفافية:

PVC/PVDC films usually have good transparency, making the products in the package visible, easy to identify and display.

– سهل المعالجة:

This film can be processed by heat sealing, cold sealing and other methods, suitable for various packaging forms.

Application scenarios of high barrier pharma grade PVC/PVDC rigid film:

– Medical device packaging

Aseptic barrier system: used for medical ostomy bag film and surgical instrument blister packaging, passed ISO 11607 microbial barrier test, and can withstand sterilization methods such as ethylene oxide (EO) and gamma rays.

Special design: The addition of lubricant and opening agent (3%-6%) solves the problem of EVA layer not easy to delaminate, and meets the dual requirements of medical ostomy bags for softness and sealing.

– التعبئة والتغليف الصيدلانية

Blister and bottle stopper: Hard film can be made into blister packaging, combined with aluminum foil heat sealing to prevent tablets and capsules from moisture oxidation. فمثلا, using PVDC90 layer packaging, the properties remain stable after being stored for 6 months at 40℃ and 75% رطوبة.

High-risk drugs: The adsorption rate of fat-soluble drugs (such as anti-tumor drugs) is lower than that of PVC monolayer film, reducing the risk of dose deviation.

– Sterilization process adaptability

High temperature sterilization: In 121℃ hot and humid steam, the film tensile strength retention rate is ≥80%, and the compression permanent deformation is ≤10%.

Irradiation stability: Gamma ray irradiation (25kGy) has little effect on the barrier properties of PVDC, which is suitable for terminal sterilization of sterile medical devices.

High-barrier pharma-grade PVC/PVDC rigid film is still the mainstream choice for drug and medical device packaging due to its excellent barrier properties, sterilization compatibility and cost advantages.