Categories

- News From Haomei (319)

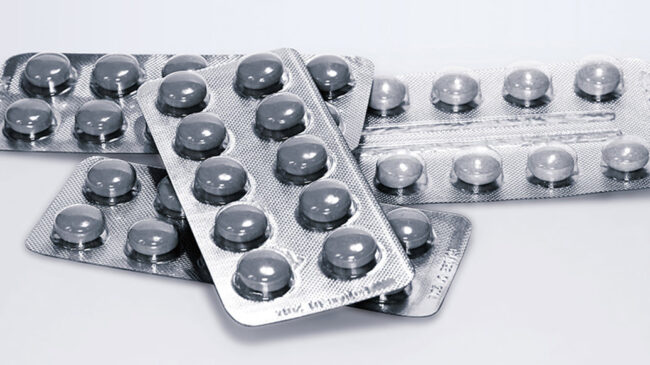

Blister packaging of pharmaceuticals is a common form of pharmaceutical packaging, usually used to pack tablets, capsules and other solid pharmaceuticals to protect the drugs from moisture, damage or external contamination. Blister packaging is widely used in the packaging of various solid pharmaceutical preparations, such as tablets, capsules, suppositories, pills and so on. It is especially suitable for drugs that require precise dosage control and are easy to carry and use.

Blister packaging of pharmaceuticals usually consists of two parts, namely, blister and backing. The blister is made of transparent plastic film, forming a bubble-shaped space for holding the drug, while the backing is made of rigid materials (such as cardboard, plastic sheets, etc.) for supporting and fixing the blister.

Blisters are generally made of plastic materials such as PVC (polyvinyl chloride) and PET (polyester film), which have good transparency, flexibility and sealing; the base plate is generally made of rigid materials such as aluminum foil, cardboard and PET (polyester film), which have a certain degree of strength and stability. Among them, polyvinyl chloride (PVC) is often preferred because of its good transparency, thermoforming, heat sealing and high air barrier, and lower cost.The thickness range of PVC is generally between 0.10 and 0.25mm, a thickness range that ensures the strength and stability of the packaging and meets the requirements of cost-effectiveness. Aluminum blister foil, on the other hand, are usually 0.012 to 0.025 mm thick. These different thicknesses of aluminum foils can meet the performance expectations of different packaging types, such as flexibility, rigidity and temper.

Blister packaging for pharmaceuticals serves the following purposes:

– Protecting role: Blister packaging can effectively protect the drugs from moisture, damage or external contamination, prolonging the shelf life and expiration date of the drugs.

– Display: The transparent blister can clearly show the appearance, color and shape of the drug, which is convenient for users to identify and choose.

– Convenient to take: Blister packs are usually designed in a form that is easy to open and take, making it convenient for users to take the medicine and take it.

Overall, blister packaging of pharmaceutical is a common form of drug packaging, with good protective performance and ease of use, suitable for a variety of solid drug packaging and sales. When choosing blister packaging for pharmaceuticals, it is necessary to choose the appropriate material, thickness and structure according to the characteristics of the medicine and packaging needs, in order to ensure the quality, safety and convenient use of medicines.