Categories

- News From Haomei (325)

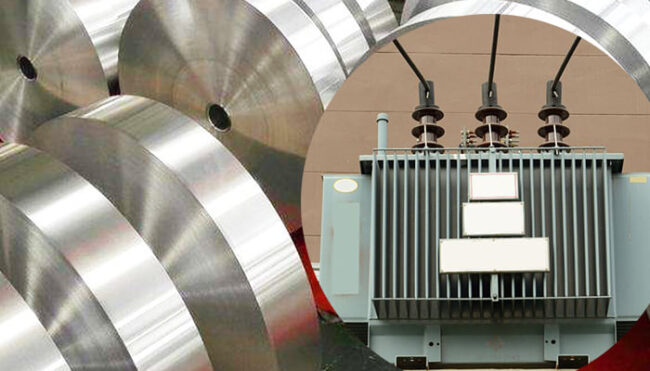

Transformer winding foil is an important part of dry type transformer with 1060, 1070 soft temper. The foil used for transformer winding are aluminium foil and copper foil, and we are specialized in producing aluminium foil and strip for transformer. Foil transformers use copper foil or aluminum foil with high conductivity as the conductive material. The thickness of the copper foil or aluminum foil is about 0.1-2.5mm, and each layer of conductor foil is one turn.

1, The transformer winding foil is lined with insulating paper, the thickness of which is 0.05-0.12mm, and diamond-shaped dispensing cable paper is generally used. Because there may be metal powder on the surface of the conductive foil board and small pinholes in the insulating paper, high-strength insulating paper should be used as interlayer insulation. The head and tail of the aluminum foil for transformer are welded to the conductive row (there are also cold-pressed connections with cold-press pliers) as the lead-out wire of the winding.

2, Foil winding direction

The winding direction of the foil winding is stipulated: from the conductive row end of the winding lead-out line, the direction of the foil plate winding is counterclockwise, that is, the left winding direction; the foil plate winding forward direction is clockwise, that is, the right winding Towards.

According to the structure of the foil winding machine and the relative position of the person to the machine, it should be: the person faces the winding machine to start winding, and the lead-out end of the conductive row points to the right, which is the left winding direction; pointing to the left, it is the right winding direction.

3, Winding of foil windings

The foil winding must be wound with a commonly used foil winding machine, and the operation is relatively simple. Follow the operating procedures of the foil winding machine.

Foil winding can also use two transformer winding foil to be wound side by side or overlapped. When overlapping winding, no transposition is performed. Two metal foil plates are overlapped and welded to the conductive bar. When winding side by side, the gap between two metal foil plates cannot be greater than 1mm, and they cannot overlap together, which can be controlled by the brake of the edge adjustment device. With automatic winding, the material can be fully utilized.