категории

- Новости От Haomei (325)

Алюминиевая фольга для фармацевтической упаковки широко используется при упаковке различных типов капсул, таблетки, гранулы и другие лекарства после приготовления и печати. Распространенные формы Haomei включают фармацевтическую блистерную упаковку., упаковка алюминий-пластик-алюминий, и т.п., и его медицинское применение одобрено фармацевтической упаковочной промышленностью.. Почему алюминиевая фольга широко используется в фармацевтической упаковочной промышленности? Каковы причины? В дополнение к предотвращению ухудшения состояния, вызванного разложением света, некоторые лекарства легко растворяются. Использование этой фармацевтической упаковки из алюминиевой фольги может эффективно предотвратить растрескивание или порчу от влаги во время транспортировки и хранения..

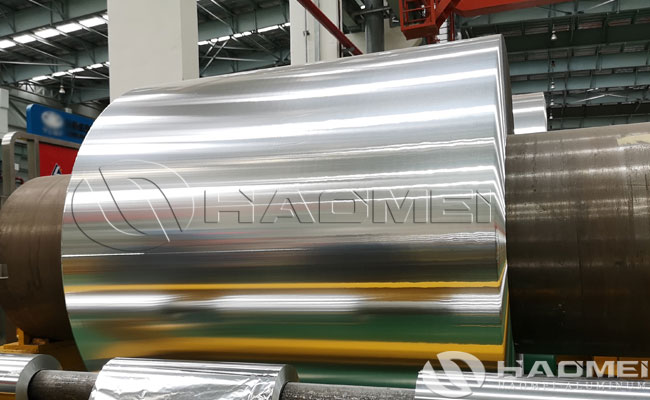

Понятно, что исходными упаковочными материалами для лекарств были пластик и бумага., но эти упаковки нелегко хранить, и легко уничтожить ингредиенты лекарств, что значительно снижает эффективность лекарства.. После непрерывных исследований и усовершенствований, наконец-то используется алюминиевая фольга, чтобы избежать недостатков пластиковой и бумажной упаковки.. А фармацевтическая упаковка из алюминиевой фольги это односторонняя алюминиевая фольга, алюминиевый сплав 8011 а также 8021, и характер О, H18. Среди них, темперамент О относительно мягкий и обычно используется при упаковке капсул и таблеток., в то время как закалка H18 относительно твердая и обычно используется в гранулированной упаковке лекарств..

Характеристики фармацевтическая упаковка из алюминиевой фольги являются:

1, Молекулярная плотность большая.; он может изолировать водяной пар и свет, И герметичный тип хорош. Потому что лекарство, которое мы принимаем, боится прилива, окисление, и свет, бумаги из алюминиевой фольги вполне достаточно.

2, Каландрируемость лучше, легче производить и разбирать. Это значит, что его легко сломать и съесть..

3, Поверхность гладкая и не легко переносит бактерии., чистый и гигиеничный.