Categories

- News From Haomei (325)

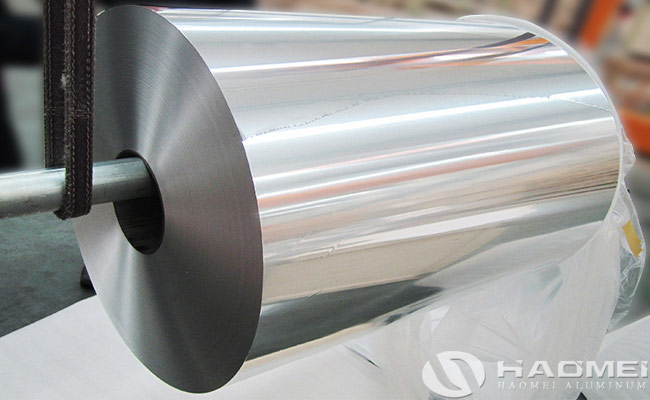

Food wrapping aluminium foil roll can use alloy raw materials 8011 and 3003 aluminum foil, which is widely applied in household and restaurant use. Food grade aluminum foil needs to be in direct contact with food when it is used, so it is preferred not to contain harmful metals such as heavy metals, and secondly it has been subjected to high temperature annealing without rolling oil. The alloy of usually used food wrapping aluminum foil is 8011, the thickness is about 0.015 or 0.02mm, the width 300 or 450mm, the coil ID is 75 and 150mm. At present, most of China’s food grade aluminum foil rolls are exported to Europe.

To achieve good performance in blocking water, blocking oxygen, protecting the fragrance, protecting from light and moisture. First of all, the selection of food packaging aluminum foil must in principle choose non-toxic, harmless, non-polluting, safe and environmentally friendly packaging materials, can not contaminate the food inside the package, causing harm to consumers. 8011 food wrapping aluminum foil has brush water grade A, flat plate shape, clean surface without oil, clean surface, uniform color, no spots, no pinholes. The aluminum foil is hot-rolled and has a tensile strength of between 123 and 135. It is suitable for aerospace wrinkle-free lunch boxes. The edges are not wrinkled after stamping and the appearance is smooth.