Categories

- News From Haomei (325)

The aluminum foil candy wrappers packaging has three main functions. One is to protect the candy product’s due luster, fragrance and shape and to extend the shelf life; the other is to prevent microbial and dust pollution, and to improve product hygiene and safety; the third is to improve the consumer’s consumer desire to buy and the value of goods.

Confectionery packaging materials mainly include: waxed paper, transparent paper, parchment paper, plastics (DPE, PVC, OPP), cellophane, aluminum foil, composite plastics (BOPP/PVDC, OPP/PVDC, OPP/LDPP), paper-plastic composites, etc. The choice of inner packaging materials is mainly based on the candy product’s requirements for air permeability, oxygen barrier, shelf life and cost. The inner packaging is generally a small package, which requires high safety. Candies are generally packaged in paper or waxed paper. For the packaging of granulated sugar sold in the form of candy boxes, it is required to have high moisture resistance and oxygen barrier properties, good printability, light protection, and fast low-temperature heat sealing. , To prevent the candy from melting by heat. If nitrocellulose coated cellophane or PVDC coated cellophane is used, the shelf life can be extended. The existing candy packaging uses traditional paper packaging. Although paper has relatively good strength, it is inferior to aluminum foil in terms of barrier properties and folding stability.

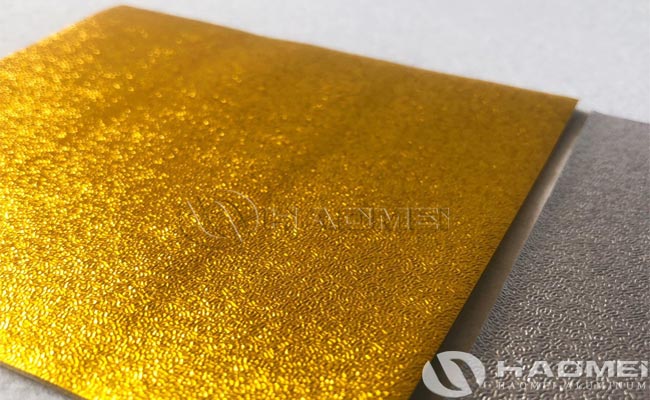

The alloy brand of aluminum foil candy wrappers is 8011 alloy aluminum foil or 1235 alloy aluminum foil or 8079 alloy aluminum foil. The thickness of the aluminum foil is 9-20um, and the width is 500-850mm. Since the object of packaging is candy, it is very important to maintain the proper appearance and good fragrance within a certain period of time. Therefore, the primary function of packaging is to help the candy product to insulate moisture, heat, and light, and maintain the proper flavor and flavor. Confectionery products are high-protein foods. It is particularly important to prevent microbial contamination. Therefore, tight packaging can avoid microbial contamination and ensure product hygiene and safety.