الاقسام

- الأخبار من Haomei (311)

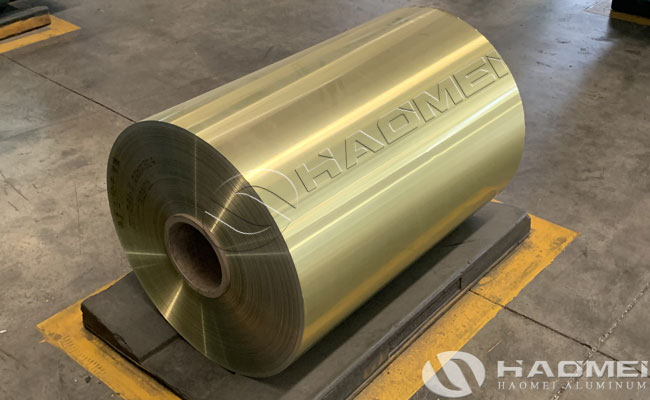

ال رقائق الألومنيوم لزعانف مكثف مكيف الهواء adopt 1060, 3102, 8011 سبيكة بمزاج H22/H24/H26. يستخدم الألومنيوم على نطاق واسع بسبب كثافته المنخفضة, الموصلية الحرارية الجيدة, معالجة سهلة, عديم الرائحة, حماية البيئة وانخفاض السعر. يعد استخدام رقائق الألومنيوم لصنع زعانف موصلة حرارياً لمبادل تكييف الهواء أحد الأمثلة على ذلك. The thickness of aluminum foil for air conditioner is 0.08~0.2mm, and the processing method is punching fin.

While ensuring the hydrophilicity of the aluminum foil surface, aluminum foil for air conditioner condenser fins maximizes the surface heat exchange area of the aluminum foil, thereby increasing the heat exchange efficiency, reducing the energy consumption of the heat exchanger, and prolonging the service life of the heat exchanger. The high convex structure blocks the airflow, effectively reducing the pressure drop and lower noise. ال رقائق الألومنيوم لمكيفات الهواء is formulated with better hydrophilicity and better heat exchange area, in order to ensure the surface hydrophilicity of the aluminum foil for heat exchangers and maximize the optimal combination of the surface heat exchange area of the aluminum foil for heat exchangers. It is convenient to reduce the cost of the mold and guide the fluid flow in the heat exchanger, thereby obtaining a better increase in the surface heat exchange area, and further improving the heat exchange efficiency of the heat exchanger.

سطح رقائق الألومنيوم لزعانف مكثف مكيف الهواء of the indoor heat exchanger is wet due to condensed water when the air conditioner is running, and it is in a dry state when the air conditioner is stopped. The dry and wet states alternately exist, making the aluminum fins prone to corrosion; while the outdoor heat exchanger, Due to the increasing air pollution, the corrosion of aluminum fins caused by acid rain has become increasingly apparent. وبالتالي, the surface of the aluminum fin needs to be treated to make it corrosion resistant.